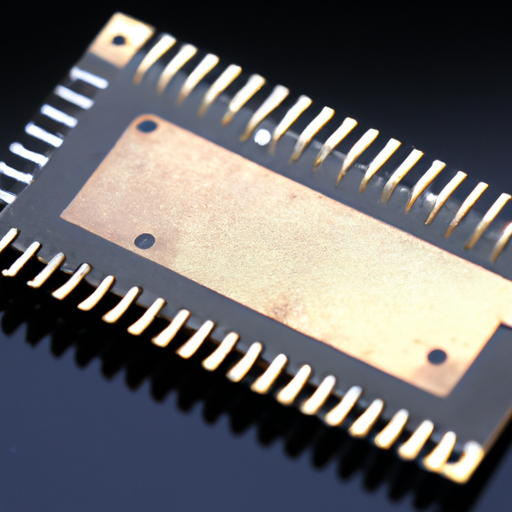

Core Functional Technologies of Aluminum Electrolytic Capacitors

1. High Capacitance Values: Aluminum electrolytic capacitors are capable of providing capacitance values that range from microfarads (µF) to several thousand microfarads (mF). This high capacitance makes them ideal for applications that require significant energy storage, such as power supply circuits and energy buffering.

2. Wide Voltage Ratings: These capacitors are available in a broad spectrum of voltage ratings, typically from 6.3V to 450V. This versatility allows them to be utilized in various applications, including high-voltage power supplies and industrial equipment.

3. Polarization: Aluminum electrolytic capacitors are polarized components, meaning they have a designated positive and negative terminal. This characteristic is critical in circuit design, as incorrect polarity can lead to catastrophic failure, including leakage or explosion.

4. Temperature Stability: While aluminum electrolytic capacitors perform well across a range of temperatures, their capacitance can vary with temperature changes. Manufacturers provide specifications for temperature coefficients, allowing engineers to select capacitors that will perform reliably in their specific operating conditions.

5. Frequency Response: Although aluminum electrolytic capacitors are not ideal for high-frequency applications due to their inherent inductance, they are effective in low to moderate frequency applications, such as power supply filtering and timing circuits.

Application Development Cases

1. Power Supply Filtering: In power supply circuits, aluminum electrolytic capacitors are essential for smoothing and filtering. They reduce voltage ripple after rectification, ensuring a stable DC output. For instance, in a power supply design utilizing the MM74HC4020N, these capacitors can be strategically placed at the output to stabilize voltage levels, enhancing the overall performance of the circuit.

2. Timing Circuits: Aluminum electrolytic capacitors can be employed in timing applications alongside resistors to create RC timing circuits. The MM74HC4020N can count pulses, while the capacitor determines timing intervals, making it suitable for applications such as timers and oscillators.

3. Audio Applications: In audio circuits, aluminum electrolytic capacitors are frequently used for coupling and decoupling signals. They block DC while allowing AC signals to pass, which is crucial in audio amplifiers and mixers, ensuring high-quality sound reproduction.

4. Decoupling and Bypass Capacitors: In digital circuits, including those utilizing the MM74HC4020N, aluminum electrolytic capacitors serve as decoupling components to filter out noise from power supply lines. This ensures stable operation of the IC by providing a local reservoir of charge, which is vital for maintaining performance during transient conditions.

5. Energy Storage in Renewable Energy Systems: Aluminum electrolytic capacitors are increasingly used in renewable energy systems, such as solar inverters, to store energy and smooth out fluctuations in power output. They help manage energy flow and improve system efficiency, making them integral to modern energy solutions.

6. Motor Control Circuits: In motor control applications, aluminum electrolytic capacitors provide the necessary energy storage for starting and running motors. They ensure smooth operation and reduce electrical noise, which is essential for maintaining the longevity and reliability of motor systems.

Conclusion

Aluminum electrolytic capacitors are versatile and essential components in modern electronics, offering high capacitance, wide voltage ratings, and stability in power supply applications. Their integration with devices like the MM74HC4020N enhances circuit performance and reliability across various applications. By understanding the core technologies and application cases of aluminum electrolytic capacitors, engineers can design more effective and efficient electronic systems, ultimately leading to improved product performance and longevity.