What are the Important Product Categories of Capacitor Casings?

I. Introduction

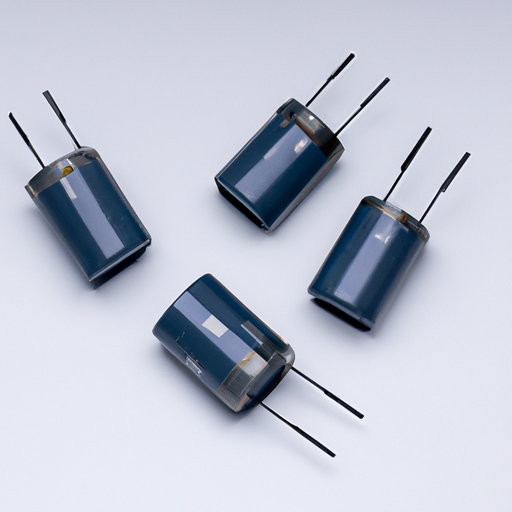

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and power flow. However, the performance and longevity of capacitors are significantly influenced by their casings. Capacitor casings provide protection against environmental factors, mechanical stress, and electrical interference. This blog post will explore the various product categories of capacitor casings, their characteristics, applications, advantages, and disadvantages, as well as the factors influencing their selection and current trends in the industry.

II. Types of Capacitor Casings

A. Aluminum Casings

**Characteristics:**

Aluminum casings are widely used due to their lightweight and durable nature. They offer excellent thermal conductivity and can withstand high temperatures, making them suitable for various applications.

**Applications:**

These casings are commonly found in power electronics, automotive applications, and consumer electronics. They are particularly favored in applications requiring high capacitance and voltage ratings.

**Advantages and Disadvantages:**

The advantages of aluminum casings include their robustness, resistance to corrosion, and ability to dissipate heat effectively. However, they can be more expensive than plastic options and may not be suitable for environments with high humidity.

B. Plastic Casings

**Characteristics:**

Plastic casings are lightweight and versatile, available in various types of plastics such as polypropylene and polyester. They provide good insulation and are resistant to moisture.

**Applications:**

Plastic casings are often used in low-voltage applications, consumer electronics, and portable devices. They are ideal for applications where weight and cost are critical factors.

**Advantages and Disadvantages:**

The primary advantage of plastic casings is their cost-effectiveness and ease of manufacturing. However, they may not offer the same level of thermal stability and mechanical strength as metal casings, making them less suitable for high-stress environments.

C. Ceramic Casings

**Characteristics:**

Ceramic casings are known for their excellent dielectric properties and high-temperature resistance. They are non-conductive and can withstand harsh environmental conditions.

**Applications:**

These casings are commonly used in high-frequency applications, telecommunications, and aerospace industries. They are ideal for applications requiring stability and reliability under extreme conditions.

**Advantages and Disadvantages:**

Ceramic casings offer superior electrical performance and thermal stability. However, they can be brittle and more expensive than other casing materials, limiting their use in certain applications.

D. Glass Casings

**Characteristics:**

Glass casings provide excellent insulation and are highly resistant to moisture and chemicals. They are often used in applications requiring high reliability and stability.

**Applications:**

Glass casings are typically found in high-voltage applications, medical devices, and military equipment. Their ability to withstand extreme conditions makes them suitable for critical applications.

**Advantages and Disadvantages:**

The advantages of glass casings include their durability and resistance to environmental factors. However, they can be heavier and more fragile than other materials, which may limit their use in portable devices.

E. Metalized Film Casings

**Characteristics:**

Metalized film casings consist of a thin layer of metal deposited on a plastic film. They offer a combination of the benefits of both metal and plastic casings.

**Applications:**

These casings are commonly used in audio equipment, power supplies, and motor drives. They are particularly effective in applications requiring high capacitance and low losses.

**Advantages and Disadvantages:**

Metalized film casings provide excellent electrical performance and are lightweight. However, they may not be as robust as aluminum or ceramic casings, making them less suitable for high-stress environments.

III. Specialized Capacitor Casings

A. High-Voltage Capacitor Casings

**Characteristics:**

High-voltage capacitor casings are designed to withstand high electrical stress and prevent breakdown. They often incorporate materials that provide excellent insulation.

**Applications:**

These casings are used in power transmission, industrial machinery, and renewable energy systems. They are critical in applications where high voltage levels are present.

**Advantages and Disadvantages:**

The primary advantage of high-voltage casings is their ability to handle extreme electrical conditions. However, they can be more expensive and may require specialized manufacturing processes.

B. High-Temperature Capacitor Casings

**Characteristics:**

High-temperature capacitor casings are engineered to operate in elevated temperature environments. They often use materials that maintain their properties at high temperatures.

**Applications:**

These casings are commonly found in automotive applications, aerospace, and industrial equipment. They are essential in environments where heat is a significant factor.

**Advantages and Disadvantages:**

The advantages of high-temperature casings include their reliability and performance in extreme conditions. However, they can be more costly and may have limitations in terms of capacitance values.

C. Waterproof and Moisture-Resistant Casings

**Characteristics:**

Waterproof and moisture-resistant casings are designed to protect capacitors from water and humidity. They often feature seals and coatings to prevent moisture ingress.

**Applications:**

These casings are used in outdoor applications, marine equipment, and any environment where exposure to moisture is a concern.

**Advantages and Disadvantages:**

The primary advantage of waterproof casings is their ability to protect sensitive components from environmental damage. However, they can be bulkier and more expensive than standard casings.

IV. Factors Influencing the Choice of Capacitor Casings

When selecting capacitor casings, several factors must be considered:

A. Electrical Properties

The electrical characteristics of the casing material, such as dielectric strength and capacitance, play a crucial role in determining the performance of the capacitor.

B. Environmental Conditions

The operating environment, including temperature, humidity, and exposure to chemicals, will influence the choice of casing material. For instance, high-temperature applications may require specialized casings.

C. Mechanical Strength

The mechanical properties of the casing, including its ability to withstand physical stress and impact, are essential for ensuring the reliability of the capacitor in various applications.

D. Cost Considerations

Cost is always a factor in material selection. While some materials may offer superior performance, they may also come with a higher price tag, which can impact the overall cost of the electronic device.

V. Innovations and Trends in Capacitor Casings

A. Advances in Materials

Recent advancements in materials science have led to the development of new casing materials that offer improved performance, durability, and environmental resistance. These innovations are driving the evolution of capacitor technology.

B. Eco-Friendly Options

With increasing awareness of environmental issues, manufacturers are exploring eco-friendly materials for capacitor casings. Biodegradable plastics and recyclable materials are gaining traction in the industry.

C. Customization and Design Trends

As electronic devices become more compact and complex, there is a growing demand for customized capacitor casings. Manufacturers are focusing on design trends that allow for better integration into modern devices while maintaining performance.

VI. Conclusion

In summary, capacitor casings play a vital role in the performance and longevity of capacitors in electronic devices. Understanding the various types of casings, their characteristics, applications, and advantages is essential for making informed decisions in the design and manufacturing of electronic components. As technology continues to evolve, innovations in materials and design will shape the future of capacitor casings, ensuring they meet the demands of increasingly sophisticated applications. Choosing the right casing is crucial for ensuring the reliability and efficiency of electronic devices, making it a key consideration for engineers and manufacturers alike.

VII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications

This comprehensive overview of capacitor casings highlights their importance in electronic devices and provides insights into the various options available, helping readers make informed choices in their applications.