Capacitor Structure Product Training Precautions

I. Introduction

Capacitors are fundamental components in the world of electronics, playing a crucial role in various applications, from power supply circuits to signal processing. At their core, capacitors store electrical energy and release it when needed, making them essential for stabilizing voltage and filtering signals. Understanding the structure and function of capacitors is vital for anyone involved in electronics, whether in design, manufacturing, or repair. This blog post aims to outline the necessary precautions for training related to capacitor structures, ensuring safety and efficiency in handling these components.

II. Understanding Capacitor Structures

A. Basic Components of a Capacitor

To appreciate the importance of safety precautions, it is essential to understand the basic components of a capacitor:

1. **Dielectric Material**: This non-conductive material separates the conductive plates and determines the capacitor's ability to store charge. Common dielectric materials include ceramic, plastic, and electrolytic substances.

2. **Conductive Plates**: These plates are typically made of metal and are responsible for storing electrical charge. The surface area and distance between the plates influence the capacitor's capacitance.

3. **Terminals**: These are the connection points for the capacitor, allowing it to be integrated into a circuit.

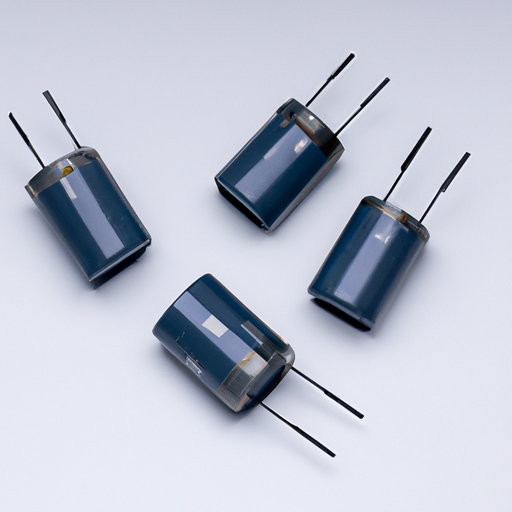

B. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Known for their stability and reliability, ceramic capacitors are widely used in high-frequency applications.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are often used in power supply circuits. However, they are polarized, meaning they must be connected correctly to avoid failure.

3. **Film Capacitors**: These capacitors are known for their low losses and are commonly used in audio and high-frequency applications.

4. **Tantalum Capacitors**: Tantalum capacitors are compact and offer high capacitance in a small package, making them ideal for portable devices.

C. Applications of Capacitors in Circuits

Capacitors are used in various applications, including:

Power Supply Filtering: Smoothing out voltage fluctuations in power supplies.

Timing Circuits: Working with resistors to create time delays in circuits.

Signal Coupling and Decoupling: Allowing AC signals to pass while blocking DC components.

III. Training Precautions Overview

A. Importance of Safety in Capacitor Handling

Handling capacitors requires a thorough understanding of safety protocols. Improper handling can lead to electric shock, component damage, and environmental hazards.

B. Common Risks Associated with Capacitors

1. **Electric Shock**: Capacitors can store significant amounts of electrical energy, posing a risk of electric shock if not handled properly.

2. **Component Damage**: Mishandling can lead to physical damage to the capacitor, affecting its performance and reliability.

3. **Environmental Hazards**: Some capacitors contain hazardous materials that require careful disposal to prevent environmental contamination.

IV. Safety Precautions During Training

A. Personal Protective Equipment (PPE)

To minimize risks, it is essential to wear appropriate personal protective equipment (PPE):

1. **Gloves**: Insulated gloves protect against electric shock and prevent skin contact with hazardous materials.

2. **Safety Glasses**: Protecting the eyes from potential debris or chemical splashes is crucial during capacitor handling.

3. **Lab Coats**: Wearing lab coats helps protect clothing and skin from exposure to hazardous materials.

B. Proper Handling Techniques

1. **Discharging Capacitors**: Always discharge capacitors before handling them. This can be done using a resistor to safely release stored energy.

2. **Avoiding Short Circuits**: Be cautious when working with multiple capacitors to prevent accidental short circuits, which can lead to component failure or injury.

3. **Using Insulated Tools**: Employ insulated tools to reduce the risk of electric shock when working with live circuits.

C. Workspace Organization

1. **Keeping Work Areas Clean**: A tidy workspace reduces the risk of accidents and makes it easier to locate tools and components.

2. **Proper Storage of Capacitors**: Store capacitors in designated areas, away from heat sources and moisture, to prevent degradation.

3. **Labeling and Signage**: Clearly label all components and work areas to ensure that everyone is aware of potential hazards.

V. Technical Training Precautions

A. Understanding Specifications and Ratings

1. **Voltage Ratings**: Always be aware of the voltage ratings of capacitors to prevent overvoltage situations that can lead to failure.

2. **Capacitance Values**: Understanding capacitance values is crucial for selecting the right capacitor for a specific application.

3. **Tolerance Levels**: Familiarize yourself with the tolerance levels of capacitors, as this affects their performance in circuits.

B. Testing and Measurement Techniques

1. **Using Multimeters**: Multimeters are essential for measuring voltage, current, and resistance in circuits involving capacitors.

2. **Oscilloscope Usage**: Oscilloscopes can help visualize the behavior of capacitors in circuits, providing insights into their performance.

3. **Load Testing**: Conducting load tests can help determine if a capacitor is functioning correctly under operational conditions.

C. Recognizing Faulty Capacitors

1. **Visual Inspection**: Regularly inspect capacitors for signs of physical damage, such as bulging or leaking.

2. **Testing for Leakage**: Use appropriate testing methods to check for leakage currents, which can indicate a failing capacitor.

3. **Identifying Physical Damage**: Be vigilant for any signs of wear or damage that could affect a capacitor's performance.

VI. Environmental Considerations

A. Disposal of Capacitors

1. **Recycling Programs**: Participate in recycling programs to ensure that capacitors are disposed of responsibly.

2. **Hazardous Waste Regulations**: Familiarize yourself with local regulations regarding the disposal of hazardous materials.

B. Impact of Capacitor Manufacturing on the Environment

1. **Material Sourcing**: Consider the environmental impact of materials used in capacitor manufacturing, such as rare metals.

2. **Energy Consumption**: Be aware of the energy consumption associated with capacitor production and seek ways to minimize it.

C. Sustainable Practices in Capacitor Use

Adopting sustainable practices, such as using energy-efficient capacitors and promoting recycling, can help reduce the environmental impact of capacitor use.

VII. Conclusion

In conclusion, understanding the structure and function of capacitors is essential for anyone involved in electronics. By adhering to the training precautions outlined in this blog post, individuals can ensure their safety and the reliability of the components they work with. Continuous learning and a commitment to responsible capacitor handling are vital for fostering a safe and efficient working environment.

VIII. References

For further reading and resources, consider the following:

Suggested Reading Materials: Books and articles on capacitor technology and safety.

Relevant Standards and Guidelines: Industry standards for capacitor handling and safety.

Additional Resources for Further Learning: Online courses and workshops focused on electronics and capacitor technology.

By following these guidelines and precautions, you can enhance your understanding of capacitors and ensure a safe and productive training experience.