An Article to Help You Understand What a Motor Capacitor Is

I. Introduction

In the world of electrical systems, motor capacitors play a crucial role in ensuring the efficient operation of various devices. But what exactly is a motor capacitor? Simply put, it is an electrical component that stores energy and releases it when needed, particularly in electric motors. Understanding motor capacitors is essential for anyone involved in the maintenance or repair of electrical appliances, as they are integral to the functionality of many devices we use daily. This article aims to provide a comprehensive overview of motor capacitors, their types, functions, applications, and maintenance.

II. What is a Motor Capacitor?

A. Basic Definition and Function

A motor capacitor is a passive electrical component that stores electrical energy in an electric field. It is primarily used in electric motors to improve their efficiency and performance. By providing an initial boost of energy, motor capacitors help start the motor and maintain its operation.

B. Types of Motor Capacitors

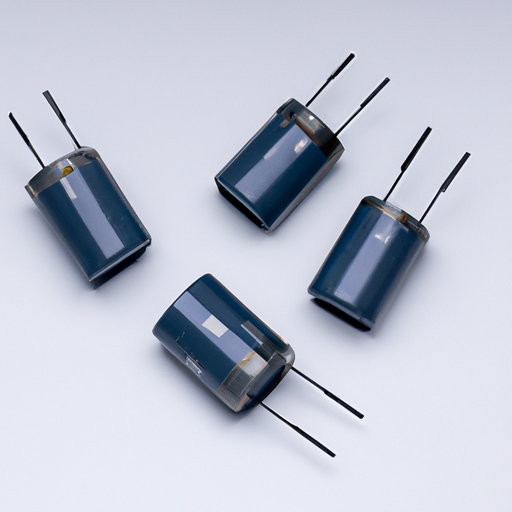

Motor capacitors can be categorized into three main types:

1. **Start Capacitors**: These capacitors provide a temporary boost of energy to help start the motor. They are typically used in single-phase motors and are disconnected from the circuit once the motor reaches a certain speed.

2. **Run Capacitors**: Unlike start capacitors, run capacitors remain in the circuit while the motor is running. They help improve the motor's efficiency and performance by providing a continuous supply of energy.

3. **Dual Capacitors**: These capacitors combine the functions of both start and run capacitors in a single unit. They are commonly used in applications where both starting and running assistance is required.

C. Key Characteristics

When selecting a motor capacitor, several key characteristics must be considered:

1. **Capacitance**: Measured in microfarads (µF), capacitance indicates the amount of electrical energy a capacitor can store. The required capacitance varies depending on the motor's specifications.

2. **Voltage Rating**: This indicates the maximum voltage the capacitor can handle without failing. It is crucial to choose a capacitor with a voltage rating that meets or exceeds the motor's operating voltage.

3. **Physical Size and Shape**: Motor capacitors come in various sizes and shapes, which can affect their installation. It's essential to ensure that the replacement capacitor fits the designated space in the appliance.

III. How Motor Capacitors Work

A. The Role of Capacitors in Electric Motors

Capacitors play a vital role in the operation of electric motors. They store electrical energy and release it at the right moment to help start the motor and maintain its operation. This process enhances the motor's efficiency and performance.

B. The Process of Starting and Running a Motor

1. **Starting Phase**: When an electric motor is powered on, the start capacitor provides an initial surge of energy to help the motor overcome inertia and begin rotating. Once the motor reaches a specific speed, a switch disconnects the start capacitor from the circuit.

2. **Running Phase**: After the motor has started, the run capacitor takes over, providing a continuous supply of energy to maintain the motor's operation. This helps improve the motor's efficiency and reduces energy consumption.

C. The Relationship Between Capacitors and Motor Efficiency

The use of motor capacitors significantly impacts the efficiency of electric motors. By providing the necessary energy during the starting phase and maintaining optimal performance during the running phase, capacitors help reduce energy waste and prolong the lifespan of the motor.

IV. Applications of Motor Capacitors

A. Common Uses in Household Appliances

Motor capacitors are found in various household appliances, including:

1. **Air Conditioners**: Capacitors help start the compressor and maintain its operation, ensuring efficient cooling.

2. **Refrigerators**: They assist in starting the compressor, which is essential for maintaining the desired temperature.

3. **Washing Machines**: Capacitors help start the motor that drives the drum, allowing for effective washing and spinning.

B. Industrial Applications

In industrial settings, motor capacitors are used in various applications, such as:

1. **Pumps**: Capacitors help start and run pumps used in water supply, irrigation, and other processes.

2. **Fans**: They assist in starting and maintaining the operation of ventilation and cooling fans.

3. **Conveyors**: Capacitors help start the motors that drive conveyor belts, ensuring smooth operation in manufacturing and logistics.

C. Importance in HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, motor capacitors are essential for the efficient operation of compressors, fans, and pumps. They help ensure that these components start and run smoothly, contributing to the overall efficiency of the system.

V. Signs of a Failing Motor Capacitor

A. Symptoms of Failure

A failing motor capacitor can lead to various issues, including:

1. **Motor Not Starting**: If the motor fails to start, it may indicate a problem with the capacitor.

2. **Overheating**: A capacitor that is failing may cause the motor to overheat, leading to potential damage.

3. **Unusual Noises**: Strange sounds, such as humming or buzzing, can indicate a failing capacitor.

B. Consequences of a Failed Capacitor

If a motor capacitor fails, it can lead to reduced efficiency, increased energy consumption, and potential damage to the motor. In some cases, a failed capacitor can cause the motor to burn out, resulting in costly repairs or replacements.

C. Importance of Timely Replacement

Regularly monitoring the condition of motor capacitors and replacing them when necessary is crucial for maintaining the efficiency and longevity of electrical appliances. Timely replacement can prevent more significant issues and save on repair costs.

VI. How to Test a Motor Capacitor

A. Tools Required for Testing

To test a motor capacitor, you will need:

- A multimeter

- Insulated gloves

- Safety goggles

B. Step-by-Step Guide to Testing

1. **Safety Precautions**: Before testing, ensure that the power to the motor is turned off and disconnected.

2. **Disconnecting the Capacitor**: Carefully disconnect the capacitor from the motor, taking note of the wiring for reinstallation.

3. **Using a Multimeter**: Set the multimeter to the capacitance setting and connect the leads to the capacitor terminals. A healthy capacitor should show a reading close to its rated capacitance.

C. Interpreting Test Results

If the multimeter reading is significantly lower than the rated capacitance or shows an open circuit, the capacitor is likely faulty and should be replaced.

VII. Replacing a Motor Capacitor

A. When to Replace a Capacitor

Capacitors should be replaced if they show signs of failure, such as bulging, leaking, or if testing indicates they are not functioning correctly.

B. Choosing the Right Replacement Capacitor

When selecting a replacement capacitor, ensure that it matches the original in terms of capacitance and voltage rating. Additionally, consider the physical dimensions to ensure a proper fit.

C. Step-by-Step Guide to Replacement

1. **Safety Precautions**: Turn off the power and wear safety gear.

2. **Disconnecting the Old Capacitor**: Carefully remove the old capacitor, noting the wiring connections.

3. **Installing the New Capacitor**: Connect the new capacitor according to the wiring diagram, ensuring secure connections.

VIII. Conclusion

Motor capacitors are essential components in electric motors, playing a vital role in their operation and efficiency. Understanding their function, applications, and maintenance can help you ensure the longevity and performance of your electrical appliances. Regular monitoring and timely replacement of motor capacitors can prevent costly repairs and enhance the efficiency of your devices.

IX. Additional Resources

For further reading and resources on motor capacitors, consider the following:

Recommended Readings: Look for books and articles on electrical systems and motor maintenance.

Online Tutorials and Videos: Many online platforms offer tutorials on testing and replacing motor capacitors.

Professional Services: If you're unsure about handling motor capacitors, consider hiring a professional for replacement and repair services.

By understanding motor capacitors and their importance, you can take proactive steps to maintain your electrical systems and ensure their efficient operation.