What Components and Modules Does Capacitor Compensation Consist Of?

Introduction

Capacitor compensation is a crucial aspect of modern electrical systems, playing a vital role in enhancing the efficiency and reliability of power distribution. By improving power factor and stabilizing voltage levels, capacitor compensation helps to optimize the performance of electrical equipment and reduce energy costs. This article will delve into the components and modules that constitute capacitor compensation systems, exploring their functions, applications, and benefits.

1. Understanding Capacitor Compensation

1.1 Definition and Purpose

Capacitor compensation refers to the use of capacitors in electrical systems to counteract the effects of inductive loads, which can lead to poor power factor and voltage instability. The primary purpose of capacitor compensation is to improve power factor, which is a measure of how effectively electrical power is being converted into useful work output. A higher power factor indicates more efficient use of electrical energy, while a lower power factor can result in increased energy costs and reduced system capacity.

1.2 Applications

Capacitor compensation finds applications across various sectors:

Industrial Applications: Factories and manufacturing plants often use large motors and inductive loads, making capacitor compensation essential for maintaining power quality and efficiency.

Commercial Applications: Retail establishments and office buildings benefit from capacitor compensation to reduce energy costs and improve the performance of lighting and HVAC systems.

Utility Applications: Electric utilities implement capacitor compensation to manage voltage levels and enhance the overall stability of the power grid.

2. Key Components of Capacitor Compensation

2.1 Capacitors

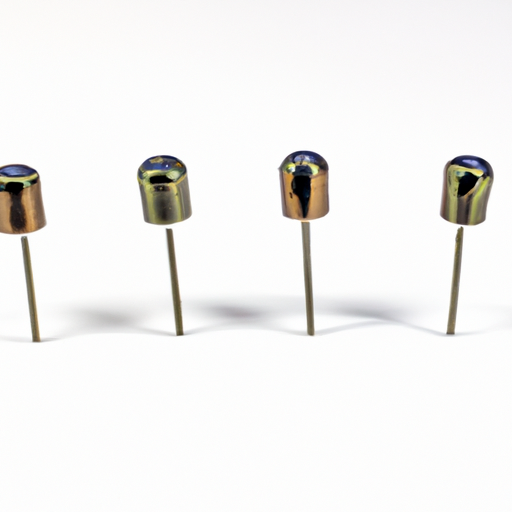

Capacitors are the primary components in capacitor compensation systems. They store and release electrical energy, helping to balance reactive power in the system. Various types of capacitors are used, including:

Fixed Capacitors: These have a constant capacitance value and are commonly used for power factor correction.

Variable Capacitors: These allow for adjustable capacitance, providing flexibility in compensation.

Power Factor Correction Capacitors: Specifically designed to improve power factor, these capacitors are often used in industrial settings.

Specifications such as voltage rating and capacitance value are critical for ensuring the capacitors can handle the system's requirements.

2.2 Reactors

Reactors, or inductors, are used in conjunction with capacitors to manage the flow of reactive power. They help to limit inrush currents and reduce the risk of overcompensation. There are two main types of reactors:

Series Reactors: Placed in series with the capacitor, they help to limit the current and improve system stability.

Parallel Reactors: Connected in parallel, these reactors can help to filter harmonics and improve overall system performance.

2.3 Switchgear

Switchgear is essential for controlling and protecting capacitor compensation systems. It includes devices such as circuit breakers and contactors, which manage the connection and disconnection of capacitors from the electrical system. Switchgear ensures safe operation and allows for maintenance without disrupting the entire system.

2.4 Control Systems

Control systems are integral to the operation of capacitor compensation systems. They monitor the power factor and voltage levels, automatically adjusting the capacitor banks as needed. Control systems can be:

Manual: Requiring human intervention to adjust settings.

Automatic: Utilizing sensors and algorithms to optimize performance without manual input.

2.5 Protection Devices

Protection devices, such as fuses and relays, are critical for safeguarding capacitor compensation systems. They detect faults and disconnect the system to prevent damage. Various types of protection devices are used, including overcurrent relays and voltage relays, ensuring the system operates safely and reliably.

3. Modules in Capacitor Compensation Systems

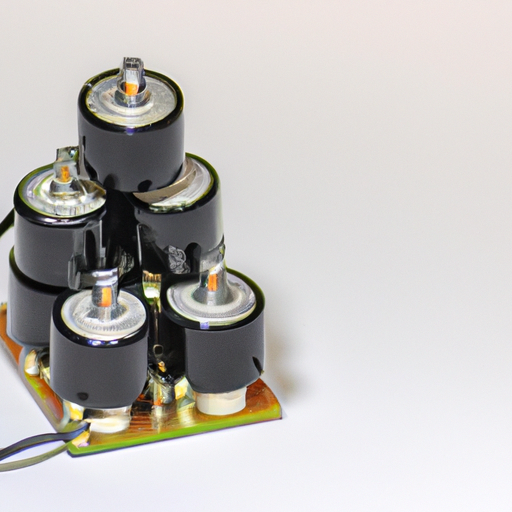

3.1 Fixed Capacitor Banks

Fixed capacitor banks consist of multiple fixed capacitors connected together. They are commonly used in industrial applications to provide a stable source of reactive power. While they are cost-effective and straightforward, they lack the flexibility of automatic systems.

3.2 Automatic Capacitor Banks

Automatic capacitor banks are equipped with control systems that adjust the capacitors based on real-time power factor measurements. This functionality allows for optimal performance and energy savings, making them ideal for dynamic loads that fluctuate throughout the day.

3.3 Synchronous Condensers

Synchronous condensers are rotating machines that provide reactive power support and voltage regulation. They can be adjusted to supply or absorb reactive power as needed, making them a versatile solution for maintaining system stability.

3.4 Harmonic Filters

Harmonic filters are essential for managing harmonic distortion in electrical systems. They help to mitigate the negative effects of harmonics, which can lead to overheating and equipment failure. There are two main types of harmonic filters:

Passive Filters: These use passive components (inductors and capacitors) to filter out specific harmonic frequencies.

Active Filters: These employ power electronics to dynamically adjust and cancel out harmonics, providing a more flexible solution.

3.5 Smart Capacitor Systems

Smart capacitor systems integrate advanced technology to optimize capacitor compensation. They can communicate with smart grid systems, allowing for real-time adjustments based on grid conditions. This technology enhances the efficiency and reliability of power distribution networks.

4. Design Considerations for Capacitor Compensation

4.1 Load Analysis

Conducting a thorough load analysis is crucial for designing an effective capacitor compensation system. This analysis helps determine the reactive power requirements and informs the selection of appropriate components. Methods for load analysis include measuring current and voltage levels and assessing the types of loads present.

4.2 System Configuration

The configuration of the capacitor compensation system can significantly impact its performance. Common configurations include delta and wye, each with its advantages and disadvantages. The choice of configuration should align with the specific needs of the electrical system.

4.3 Environmental Factors

Environmental conditions, such as temperature and humidity, can affect the performance and reliability of capacitor compensation systems. Selecting components that can withstand these conditions is essential for ensuring long-term operation.

5. Benefits of Capacitor Compensation

5.1 Improved Power Factor

One of the primary benefits of capacitor compensation is the improvement of power factor. By reducing the amount of reactive power drawn from the grid, capacitor compensation enhances the efficiency of electrical systems, leading to lower energy costs.

5.2 Voltage Stabilization

Capacitor compensation plays a vital role in stabilizing voltage levels within electrical systems. By providing reactive power support, capacitors help maintain voltage within acceptable limits, benefiting both equipment performance and overall system reliability.

5.3 Energy Savings

Improving power factor and stabilizing voltage levels can lead to significant energy savings. Reduced energy losses translate to lower utility bills, making capacitor compensation an economically advantageous solution for businesses and utilities alike.

6. Challenges and Limitations

6.1 Overcompensation

One of the risks associated with capacitor compensation is overcompensation, which can lead to voltage rise and system instability. To mitigate this risk, careful monitoring and control of capacitor banks are essential.

6.2 Harmonic Distortion

Harmonic distortion can negatively impact capacitor systems, leading to overheating and reduced efficiency. Implementing harmonic filters and conducting regular assessments can help manage these issues.

6.3 Maintenance and Reliability

Regular maintenance is crucial for ensuring the reliability of capacitor compensation systems. Common issues include capacitor failure and control system malfunctions. Establishing a maintenance schedule and conducting routine inspections can help prevent these problems.

Conclusion

Capacitor compensation is a vital component of modern electrical systems, providing numerous benefits such as improved power factor, voltage stabilization, and energy savings. Understanding the key components and modules involved in capacitor compensation is essential for designing effective systems that meet the needs of various applications. As technology continues to evolve, the future of capacitor compensation will likely see advancements in smart systems and enhanced integration with renewable energy sources, further optimizing power distribution and efficiency.

References

- IEEE Standards for Power Factor Correction

- "Power Quality in Power Systems" by C. Sankaran

- "Electrical Power Systems" by C.L. Wadhwa

- Industry reports on capacitor compensation technologies and applications.

This blog post provides a comprehensive overview of capacitor compensation, its components, modules, and the benefits it offers to electrical systems. By understanding these elements, stakeholders can make informed decisions about implementing capacitor compensation solutions in their operations.