Popular Compensation Capacitor Product Models

I. Introduction

A. Definition of Compensation Capacitors

Compensation capacitors are electrical components designed to improve the power factor in electrical systems. They store and release electrical energy, helping to stabilize voltage levels and reduce losses in power distribution. By compensating for reactive power, these capacitors enhance the efficiency of electrical systems, making them a crucial element in modern electrical engineering.

B. Importance of Compensation Capacitors in Electrical Systems

In industrial and commercial settings, the demand for electricity is ever-increasing. However, many electrical devices, particularly inductive loads like motors and transformers, consume reactive power, which can lead to inefficiencies. Compensation capacitors mitigate these issues by providing reactive power locally, thus improving the overall power factor. This not only reduces energy costs but also minimizes the risk of equipment damage and enhances system reliability.

C. Overview of the Article's Purpose

This article aims to explore popular compensation capacitor product models available in the market today. We will delve into their features, applications, and the leading manufacturers that produce these essential components. By the end of this article, readers will have a comprehensive understanding of compensation capacitors and be better equipped to select the right model for their needs.

II. Understanding Compensation Capacitors

A. What are Compensation Capacitors?

1. Function and Purpose

Compensation capacitors serve to counteract the effects of inductive loads in electrical systems. They provide reactive power, which helps to maintain voltage levels and improve the power factor. This is particularly important in industrial settings where large motors and other inductive devices are prevalent.

2. Types of Compensation Capacitors

There are several types of compensation capacitors, including:

Fixed Capacitors: These are designed for specific applications and cannot be adjusted.

Variable Capacitors: These allow for adjustments in capacitance, making them versatile for different applications.

Power Factor Correction Capacitors: Specifically designed to improve power factor in electrical systems.

B. Applications of Compensation Capacitors

1. Power Factor Correction

One of the primary applications of compensation capacitors is power factor correction. By providing reactive power, these capacitors help to reduce the phase difference between voltage and current, leading to a more efficient power system.

2. Voltage Regulation

Compensation capacitors also play a vital role in voltage regulation. By stabilizing voltage levels, they ensure that electrical equipment operates within safe limits, reducing the risk of damage and improving overall system performance.

3. Harmonic Filtering

In addition to power factor correction and voltage regulation, compensation capacitors can help filter out harmonics in electrical systems. This is essential for maintaining the quality of power and protecting sensitive equipment from voltage distortions.

III. Key Features of Compensation Capacitors

A. Capacitance Value

The capacitance value of a compensation capacitor is a critical factor that determines its effectiveness in a given application. It is measured in farads (F) and should be selected based on the specific requirements of the electrical system.

B. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without failure. It is essential to choose a capacitor with a voltage rating that exceeds the maximum operating voltage of the system.

C. Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature. A low temperature coefficient is desirable for applications where temperature fluctuations are common.

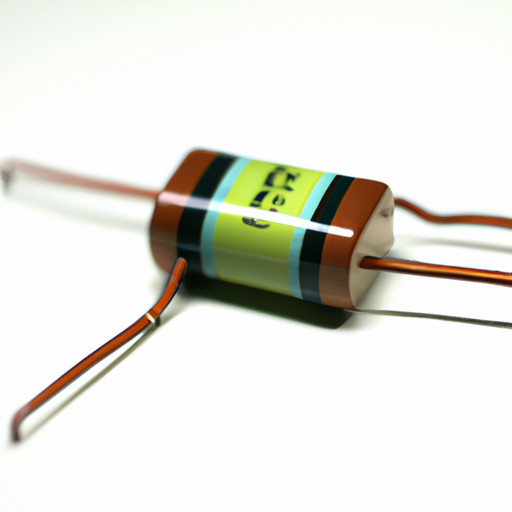

D. Dielectric Material

The dielectric material used in compensation capacitors affects their performance and reliability. Common materials include polypropylene, polyester, and ceramic, each with its own advantages and disadvantages.

E. Size and Form Factor

The physical size and form factor of compensation capacitors can impact their installation and integration into existing systems. Compact designs are often preferred in space-constrained environments.

IV. Popular Compensation Capacitor Product Models

A. Overview of Leading Manufacturers

Several manufacturers are recognized for their high-quality compensation capacitors. These include:

1. **Schneider Electric**

2. **Siemens**

3. **ABB**

4. **Eaton**

5. **Vishay**

B. Detailed Review of Popular Models

1. Schneider Electric's VarSet Series

Features and Specifications: The VarSet series offers a range of fixed and automatic power factor correction capacitors. They are designed for high reliability and efficiency, with capacitance values ranging from 5 kVAR to 1000 kVAR.

Applications and Use Cases: Ideal for industrial applications, the VarSet series is commonly used in manufacturing plants and commercial buildings to improve power factor and reduce energy costs.

2. Siemens' SIVACON Series

Features and Specifications: The SIVACON series includes modular capacitor banks that can be customized to meet specific requirements. They feature advanced monitoring capabilities and are designed for easy installation.

Applications and Use Cases: These capacitors are suitable for large industrial facilities and utility applications, providing effective power factor correction and voltage stabilization.

3. ABB's Capacitor Banks

Features and Specifications: ABB offers a range of capacitor banks designed for both indoor and outdoor applications. They are known for their robust construction and high performance, with options for automatic control.

Applications and Use Cases: Commonly used in substations and industrial plants, ABB's capacitor banks help improve power quality and reduce energy losses.

4. Eaton's Power Factor Correction Capacitors

Features and Specifications: Eaton's capacitors are designed for reliability and efficiency, with a variety of capacitance values and voltage ratings. They are built to withstand harsh environmental conditions.

Applications and Use Cases: These capacitors are widely used in commercial and industrial settings for power factor correction and voltage support.

5. Vishay's Capacitor Solutions

Features and Specifications: Vishay offers a range of compensation capacitors with various dielectric materials and capacitance values. They are known for their high reliability and performance.

Applications and Use Cases: Vishay's capacitors are suitable for a wide range of applications, including consumer electronics, automotive, and industrial equipment.

V. Comparison of Compensation Capacitor Models

A. Performance Metrics

1. Efficiency

Efficiency is a critical metric when evaluating compensation capacitors. High-efficiency models can significantly reduce energy losses and improve overall system performance.

2. Reliability

Reliability is essential for ensuring the longevity of compensation capacitors. Models from reputable manufacturers often come with warranties and are tested for durability under various conditions.

3. Cost-Effectiveness

Cost-effectiveness is a key consideration for many businesses. While initial costs may vary, the long-term savings from improved power factor and reduced energy costs can make certain models more attractive.

B. Suitability for Different Applications

1. Industrial vs. Commercial Use

Different applications may require different types of compensation capacitors. Industrial settings often demand higher capacitance values and robust designs, while commercial applications may prioritize compactness and ease of installation.

2. Specific Industry Requirements

Certain industries, such as manufacturing and utilities, may have specific requirements for compensation capacitors, including compliance with regulatory standards and the ability to handle high loads.

VI. Trends in Compensation Capacitor Technology

A. Innovations in Design and Materials

Recent advancements in materials and design have led to more efficient and compact compensation capacitors. Manufacturers are increasingly using advanced dielectric materials that enhance performance and reliability.

B. Smart Capacitor Solutions

The integration of smart technology into compensation capacitors is a growing trend. Smart capacitors can monitor system performance in real-time, allowing for automatic adjustments and improved efficiency.

C. Environmental Considerations and Sustainability

As sustainability becomes a priority for many industries, manufacturers are focusing on eco-friendly materials and designs. This includes the use of recyclable materials and energy-efficient production processes.

VII. Conclusion

A. Summary of Key Points

Compensation capacitors play a vital role in improving the efficiency and reliability of electrical systems. With various types and models available, it is essential to understand their features and applications to make informed decisions.

B. Importance of Selecting the Right Compensation Capacitor

Choosing the right compensation capacitor can lead to significant energy savings and improved system performance. Factors such as capacitance value, voltage rating, and application requirements should be carefully considered.

C. Future Outlook for Compensation Capacitor Products

As technology continues to evolve, we can expect further innovations in compensation capacitors, including smarter solutions and more sustainable designs. This will enhance their effectiveness in meeting the growing demands of modern electrical systems.

VIII. References

A. Cited Works

- Manufacturer specifications and product datasheets

- Industry publications on electrical engineering and power systems

B. Further Reading and Resources

- IEEE publications on power factor correction

- Technical articles on capacitor technology and applications

By understanding the various compensation capacitor models and their applications, readers can make informed choices that enhance the efficiency and reliability of their electrical systems.