What are the Advantages of Aluminum Electrolytic Capacitor Products?

I. Introduction

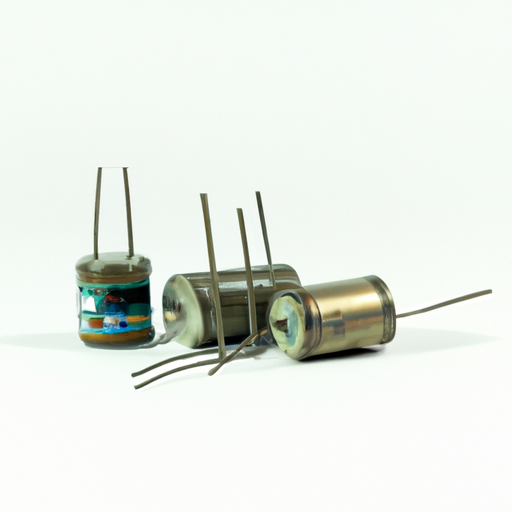

Aluminum electrolytic capacitors are a type of capacitor that utilizes an aluminum oxide layer as the dielectric material. These components are essential in electronic circuits, serving various functions such as energy storage, filtering, and signal coupling. Their unique properties make them a popular choice in many applications, from consumer electronics to industrial machinery. This article will explore the advantages of aluminum electrolytic capacitors, highlighting their significance in modern electronics.

II. Basic Principles of Aluminum Electrolytic Capacitors

A. Construction and Components

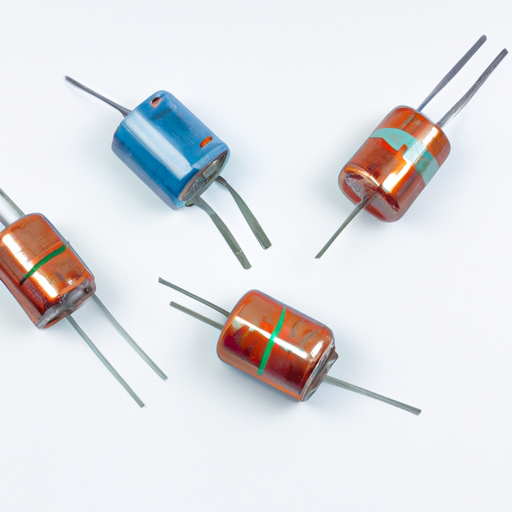

Aluminum electrolytic capacitors consist of three primary components: the anode, cathode, and electrolyte.

1. **Anode and Cathode**: The anode is typically made of aluminum foil, which is oxidized to form a thin layer of aluminum oxide. This oxide layer acts as the dielectric. The cathode is usually a conductive liquid or solid that interacts with the electrolyte.

2. **Electrolyte**: The electrolyte is a conductive solution that allows ions to move between the anode and cathode, facilitating the capacitor's charge storage capabilities.

3. **Dielectric Layer**: The aluminum oxide layer serves as the dielectric, providing insulation between the anode and cathode while allowing for the storage of electrical energy.

B. Working Mechanism

1. **Charge Storage**: When a voltage is applied across the capacitor, positive charges accumulate on the anode, while negative charges gather on the cathode. This separation of charge creates an electric field, allowing the capacitor to store energy.

2. **Capacitance and Voltage Ratings**: The capacitance of an aluminum electrolytic capacitor is determined by the surface area of the anode, the thickness of the dielectric layer, and the dielectric constant of the material. These capacitors are available in various voltage ratings, making them suitable for different applications.

III. Key Advantages of Aluminum Electrolytic Capacitors

A. High Capacitance Values

One of the most significant advantages of aluminum electrolytic capacitors is their ability to achieve high capacitance values.

1. **Comparison with Other Capacitor Types**: Compared to ceramic or film capacitors, aluminum electrolytic capacitors can provide much higher capacitance in a relatively small package. This makes them ideal for applications requiring substantial energy storage.

2. **Applications Requiring High Capacitance**: High capacitance values are particularly beneficial in power supply circuits, audio equipment, and other applications where large amounts of energy need to be stored and released quickly.

B. Cost-Effectiveness

Aluminum electrolytic capacitors are known for their cost-effectiveness.

1. **Manufacturing Process**: The manufacturing process for these capacitors is relatively straightforward and efficient, contributing to lower production costs.

2. **Market Pricing**: As a result, aluminum electrolytic capacitors are often more affordable than other types of capacitors, making them a popular choice for manufacturers looking to reduce costs without sacrificing performance.

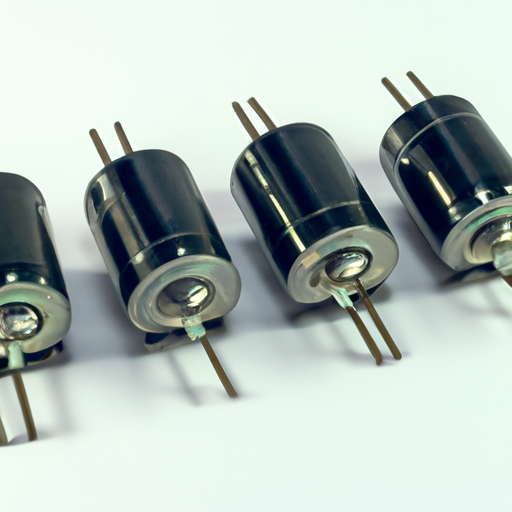

C. Size and Form Factor

The compact design of aluminum electrolytic capacitors allows for versatility in various applications.

1. **Compact Design**: These capacitors can be produced in various sizes, making them suitable for both small and large electronic devices.

2. **Versatility in Applications**: Their small form factor enables their use in tight spaces, such as in smartphones, laptops, and other portable devices.

D. Voltage Ratings

Aluminum electrolytic capacitors come with a wide range of voltage ratings.

1. **Wide Range of Voltage Ratings**: This variety allows engineers to select capacitors that meet the specific voltage requirements of their applications, ensuring optimal performance.

2. **Suitability for Various Applications**: Whether in low-voltage consumer electronics or high-voltage industrial equipment, aluminum electrolytic capacitors can be tailored to fit the needs of diverse applications.

E. Temperature Stability

These capacitors exhibit excellent temperature stability.

1. **Operating Temperature Range**: Aluminum electrolytic capacitors can operate effectively across a broad temperature range, typically from -40°C to +105°C, depending on the specific design.

2. **Performance in Harsh Environments**: This temperature stability makes them suitable for use in harsh environments, such as automotive and industrial applications, where temperature fluctuations are common.

F. Reliability and Longevity

Aluminum electrolytic capacitors are known for their reliability and longevity.

1. **Lifespan and Endurance**: With proper usage and derating, these capacitors can have a long lifespan, often exceeding several thousand hours of operation.

2. **Failure Modes and Mitigation**: While they can fail due to factors like excessive voltage or temperature, manufacturers have developed various strategies to mitigate these risks, enhancing their overall reliability.

IV. Applications of Aluminum Electrolytic Capacitors

A. Consumer Electronics

Aluminum electrolytic capacitors are widely used in consumer electronics.

1. **Power Supply Circuits**: They play a crucial role in smoothing out voltage fluctuations in power supply circuits, ensuring stable operation.

2. **Audio Equipment**: In audio applications, these capacitors help filter out noise and improve sound quality.

B. Industrial Applications

In industrial settings, aluminum electrolytic capacitors are essential components.

1. **Motor Drives**: They are used in motor drive circuits to provide the necessary energy storage for efficient operation.

2. **Power Electronics**: These capacitors are integral to various power electronic devices, including inverters and converters.

C. Automotive Industry

The automotive industry relies heavily on aluminum electrolytic capacitors.

1. **Electric Vehicles**: In electric vehicles, they are used in battery management systems and power electronics to ensure efficient energy use.

2. **Infotainment Systems**: These capacitors also support infotainment systems, providing stable power for audio and visual components.

D. Renewable Energy Systems

Aluminum electrolytic capacitors are increasingly used in renewable energy systems.

1. **Solar Inverters**: They help manage energy storage and conversion in solar inverters, ensuring efficient operation.

2. **Wind Turbines**: In wind energy applications, these capacitors support power conditioning and grid integration.

V. Challenges and Limitations

Despite their many advantages, aluminum electrolytic capacitors do have some challenges and limitations.

A. Leakage Current

One of the primary concerns with aluminum electrolytic capacitors is leakage current, which can lead to energy loss and reduced efficiency.

B. Voltage Derating

To ensure reliability, these capacitors often require voltage derating, which can limit their use in high-voltage applications.

C. Size Constraints in High-Frequency Applications

While they are compact, aluminum electrolytic capacitors may not perform well in high-frequency applications due to their inherent inductance.

D. Environmental Concerns

The use of electrolytes and the potential for leakage can raise environmental concerns, prompting manufacturers to seek more eco-friendly alternatives.

VI. Future Trends and Innovations

The future of aluminum electrolytic capacitors looks promising, with several trends and innovations on the horizon.

A. Advancements in Materials

Research into new materials may lead to improved performance and reliability, enhancing the capabilities of aluminum electrolytic capacitors.

B. Miniaturization and Integration

As electronic devices continue to shrink, the demand for smaller, more integrated capacitors will grow, driving innovation in design and manufacturing.

C. Eco-Friendly Alternatives

With increasing environmental awareness, manufacturers are exploring eco-friendly alternatives to traditional electrolytes, aiming to reduce the environmental impact of these components.

D. Smart Capacitor Technologies

The development of smart capacitor technologies, which can monitor and adjust their performance in real-time, may revolutionize how aluminum electrolytic capacitors are used in modern electronics.

VII. Conclusion

In summary, aluminum electrolytic capacitors offer numerous advantages, including high capacitance values, cost-effectiveness, compact design, and reliability. Their versatility makes them suitable for a wide range of applications, from consumer electronics to renewable energy systems. As technology continues to advance, the importance of aluminum electrolytic capacitors in modern electronics will only grow, paving the way for innovative solutions and improved performance in various fields.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications

This comprehensive overview highlights the advantages of aluminum electrolytic capacitors, emphasizing their critical role in the ever-evolving landscape of electronics. As we look to the future, these components will undoubtedly continue to play a vital role in shaping the technology of tomorrow.