Precautions for Training Magnetic Bead Inductor Products

I. Introduction

A. Definition of Magnetic Bead Inductors

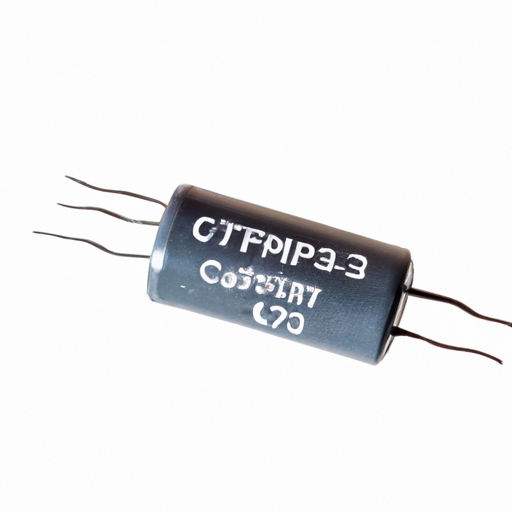

Magnetic bead inductors are passive electronic components that play a crucial role in filtering and managing electrical signals in various electronic devices. They are designed to suppress high-frequency noise and provide impedance matching, making them essential in applications ranging from telecommunications to consumer electronics.

B. Importance of Training in Magnetic Bead Inductor Products

Training in the production and handling of magnetic bead inductors is vital for ensuring product quality and reliability. As these components are integral to the performance of electronic devices, proper training helps manufacturers maintain high standards and minimize defects.

C. Purpose of the Document

This document aims to outline the precautions necessary for training personnel involved in the production of magnetic bead inductors. By adhering to these precautions, manufacturers can enhance product quality, ensure safety, and foster a culture of continuous improvement.

II. Understanding Magnetic Bead Inductors

A. Overview of Magnetic Bead Inductors

1. Functionality

Magnetic bead inductors function by providing inductance to electrical circuits, which helps in filtering out unwanted high-frequency signals. They are particularly effective in reducing electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring that electronic devices operate smoothly without disruptions.

2. Applications in Electronics

These inductors are widely used in various applications, including power supplies, signal processing, and data transmission. They are found in devices such as smartphones, computers, and automotive electronics, where they help maintain signal integrity and enhance overall performance.

B. Types of Magnetic Bead Inductors

1. Ferrite Beads

Ferrite beads are passive components that provide high impedance at high frequencies while allowing low-frequency signals to pass through. They are commonly used in power supply circuits to suppress noise.

2. Common Mode Chokes

Common mode chokes are designed to filter out common mode noise in differential signal lines. They are essential in applications where signal integrity is critical, such as in data communication systems.

3. Differential Mode Inductors

Differential mode inductors are used to filter differential signals, ensuring that unwanted noise does not affect the integrity of the transmitted data. They are often employed in high-speed data lines.

III. Importance of Precautions in Training

A. Safety Considerations

1. Electrical Safety

Training personnel on electrical safety is paramount. Employees must understand the risks associated with working with electrical components and be equipped with the knowledge to mitigate these risks. This includes proper use of personal protective equipment (PPE) and adherence to safety protocols.

2. Handling of Materials

Proper handling of materials is essential to prevent accidents and ensure product quality. Employees should be trained on the correct methods for handling magnetic bead inductors and associated materials to avoid damage and contamination.

B. Quality Assurance

1. Consistency in Production

Training ensures that all personnel follow standardized procedures, leading to consistent production quality. This consistency is crucial for maintaining the reliability of magnetic bead inductors.

2. Reducing Defects and Failures

By emphasizing the importance of quality assurance during training, manufacturers can significantly reduce the likelihood of defects and failures in their products. This not only enhances customer satisfaction but also reduces costs associated with returns and repairs.

IV. Precautions for Training Magnetic Bead Inductor Products

A. Material Handling

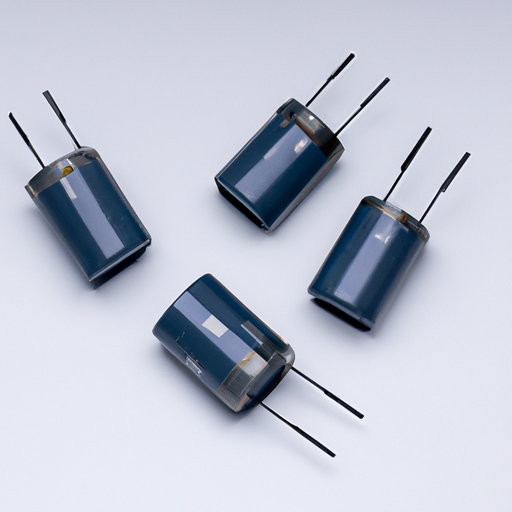

1. Proper Storage Conditions

Magnetic bead inductors should be stored in controlled environments to prevent damage from humidity, temperature fluctuations, and contamination. Training personnel on proper storage techniques is essential for maintaining product integrity.

2. Avoiding Contamination

Contamination can lead to significant performance issues in magnetic bead inductors. Employees should be trained on best practices for handling and transporting materials to minimize the risk of contamination.

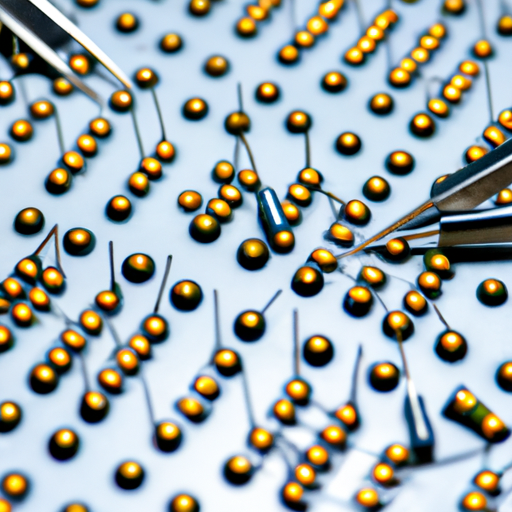

B. Equipment Safety

1. Calibration of Tools

Regular calibration of tools and equipment is necessary to ensure accurate measurements and consistent production quality. Training should include procedures for checking and calibrating equipment.

2. Regular Maintenance of Machinery

Routine maintenance of machinery is crucial for preventing breakdowns and ensuring smooth operations. Personnel should be trained on maintenance schedules and procedures to keep equipment in optimal condition.

C. Environmental Considerations

1. Temperature and Humidity Control

Maintaining appropriate temperature and humidity levels in the production environment is vital for the performance of magnetic bead inductors. Training should cover the importance of environmental controls and how to monitor them effectively.

2. Cleanroom Standards

For certain applications, cleanroom standards may be necessary to prevent contamination. Training personnel on cleanroom protocols and practices is essential for ensuring compliance and product quality.

D. Training Personnel

1. Comprehensive Training Programs

Developing comprehensive training programs that cover all aspects of magnetic bead inductor production is essential. These programs should include theoretical knowledge, practical skills, and safety protocols.

2. Importance of Continuous Education

The field of electronics is constantly evolving, and continuous education is necessary to keep personnel updated on the latest technologies and best practices. Manufacturers should encourage ongoing training and professional development.

E. Testing and Quality Control

1. Pre-Production Testing

Conducting pre-production testing is crucial for identifying potential issues before mass production begins. Training should emphasize the importance of thorough testing and the methods used to evaluate product performance.

2. In-Process Quality Checks

Implementing in-process quality checks helps catch defects early in the production process. Personnel should be trained on how to conduct these checks effectively and the criteria for evaluating product quality.

3. Final Product Evaluation

Final product evaluation is the last line of defense against defects. Training should cover the procedures for conducting final inspections and the importance of adhering to quality standards.

V. Common Challenges and Solutions

A. Identifying Potential Risks

Identifying potential risks in the production of magnetic bead inductors is essential for implementing effective precautions. Training should include risk assessment techniques and how to recognize hazards in the workplace.

B. Implementing Effective Solutions

Once risks are identified, it is crucial to implement effective solutions. Training should focus on problem-solving techniques and how to develop and implement corrective actions.

C. Case Studies of Successful Training Programs

Analyzing case studies of successful training programs can provide valuable insights into best practices. Manufacturers should share success stories and lessons learned to foster a culture of continuous improvement.

VI. Conclusion

A. Recap of Key Precautions

In summary, training in the production of magnetic bead inductors requires a comprehensive approach that emphasizes safety, quality assurance, and environmental considerations. By adhering to the precautions outlined in this document, manufacturers can enhance product quality and ensure the safety of their personnel.

B. The Role of Precautions in Enhancing Product Quality

Precautions play a critical role in enhancing the quality of magnetic bead inductors. By investing in training and implementing best practices, manufacturers can reduce defects, improve consistency, and ultimately deliver superior products to their customers.

C. Future Directions in Magnetic Bead Inductor Training

As technology continues to advance, the training of personnel involved in the production of magnetic bead inductors must evolve as well. Manufacturers should stay abreast of industry trends and innovations to ensure their training programs remain relevant and effective.

VII. References

A. Academic Journals

- Articles and studies on magnetic bead inductors and their applications in electronics.

B. Industry Standards and Guidelines

- Relevant standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

C. Manufacturer Specifications and Manuals

- Specifications and manuals from manufacturers of magnetic bead inductors, providing insights into best practices and quality standards.

---

By following the precautions outlined in this document, manufacturers can ensure that their training programs for magnetic bead inductor products are effective, safe, and conducive to producing high-quality components.