The Role of Magnetic Ring Inductor Products in Practical Applications

I. Introduction

In the realm of electrical engineering, inductors play a pivotal role in the functioning of various electronic devices. Among the different types of inductors, magnetic ring inductors stand out due to their unique design and efficiency. This blog post delves into the significance of magnetic ring inductors, exploring their structure, types, applications, advantages, challenges, and future trends.

II. Understanding Magnetic Ring Inductors

A. Structure and Composition

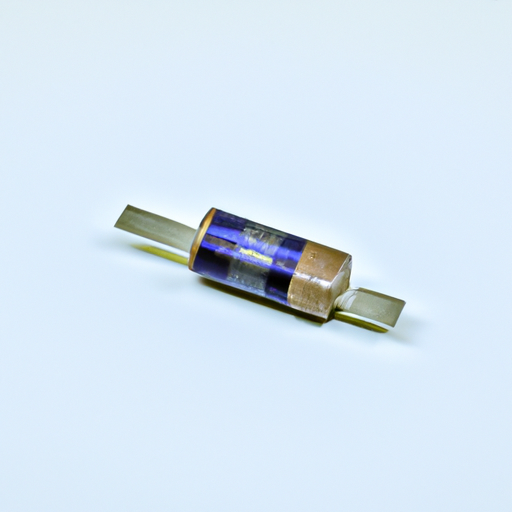

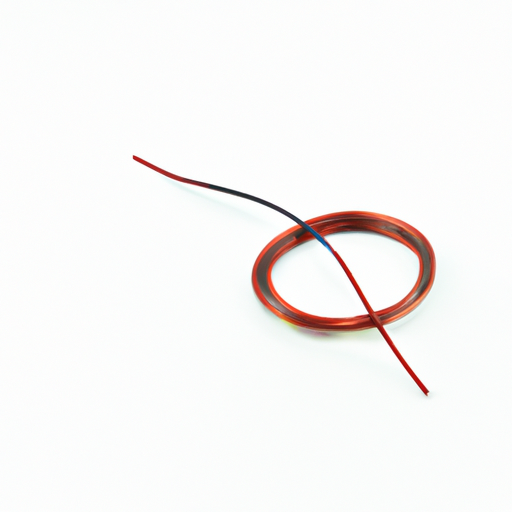

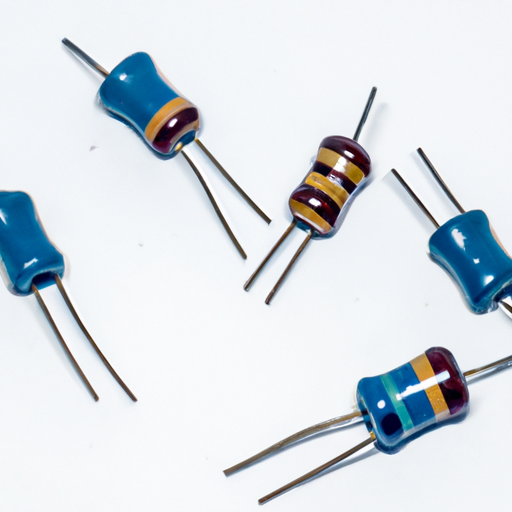

Magnetic ring inductors are characterized by their toroidal shape, which allows for efficient magnetic field generation. The core of these inductors is typically made from materials such as ferrite or iron powder, chosen for their magnetic properties. Ferrite cores are particularly popular due to their high permeability and low losses at high frequencies, making them ideal for RF applications. Iron powder cores, on the other hand, are often used in applications requiring higher inductance values.

The wire winding techniques used in constructing magnetic ring inductors also play a crucial role in their performance. The number of turns, the gauge of the wire, and the winding pattern can all influence the inductor's inductance and resistance characteristics.

B. Operating Principles

The fundamental operating principle of magnetic ring inductors revolves around the concept of inductance, which is the ability of a coil to store energy in a magnetic field when an electric current passes through it. When current flows through the inductor, it generates a magnetic field around the core. This magnetic field stores energy, which can be released back into the circuit when the current changes. This energy storage and release mechanism is essential for various applications, including filtering and energy conversion.

III. Types of Magnetic Ring Inductors

A. Common Types and Their Characteristics

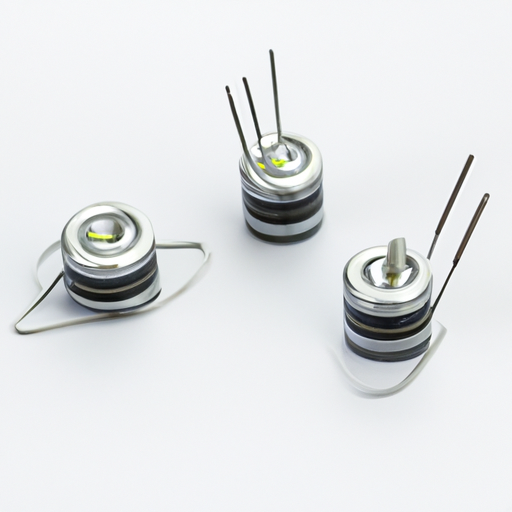

1. **Air Core Inductors**: These inductors do not use a magnetic core, relying solely on air as the medium. While they are less efficient than their magnetic counterparts, they are often used in high-frequency applications where core losses would be detrimental.

2. **Ferrite Core Inductors**: Ferrite cores are widely used in magnetic ring inductors due to their high magnetic permeability and low eddy current losses. They are ideal for applications in the RF range and are commonly found in power supply circuits.

3. **Iron Powder Core Inductors**: These inductors utilize iron powder as the core material, providing a good balance between cost and performance. They are often used in applications requiring higher inductance values and are known for their ability to handle higher currents.

B. Selection Criteria for Different Applications

When selecting a magnetic ring inductor for a specific application, several factors must be considered, including the required inductance value, current rating, frequency range, and environmental conditions. Understanding these criteria ensures that the chosen inductor will perform optimally in its intended application.

IV. Applications of Magnetic Ring Inductors

A. Power Supply Circuits

Magnetic ring inductors are integral components in power supply circuits, particularly in DC-DC converters and switching power supplies. In these applications, they help regulate voltage levels and improve efficiency by minimizing energy losses during the conversion process. The inductors store energy during the switching cycle and release it when needed, ensuring a stable output voltage.

B. Signal Processing

In signal processing applications, magnetic ring inductors are used for filtering and impedance matching. They can effectively filter out unwanted frequencies, allowing only the desired signals to pass through. This capability is crucial in audio equipment, communication devices, and other electronic systems where signal integrity is paramount.

C. RF Applications

Magnetic ring inductors play a vital role in radio frequency (RF) applications, such as antenna matching and RF amplifiers. They help match the impedance of antennas to the transmission line, maximizing power transfer and minimizing signal loss. Additionally, they are used in RF amplifiers to enhance signal strength and improve overall performance.

D. Energy Storage Systems

In energy storage systems, magnetic ring inductors are employed in energy harvesting applications and renewable energy systems. They can store energy generated from renewable sources, such as solar or wind, and release it when needed. This capability is essential for ensuring a stable energy supply and optimizing the use of renewable resources.

V. Advantages of Magnetic Ring Inductors

A. High Efficiency and Performance

One of the primary advantages of magnetic ring inductors is their high efficiency. The toroidal shape minimizes magnetic leakage and reduces core losses, resulting in better performance compared to other inductor types. This efficiency is particularly important in power supply applications, where energy conservation is critical.

B. Compact Size and Design Flexibility

Magnetic ring inductors are compact and can be designed to fit into various form factors, making them suitable for a wide range of applications. Their small size allows for more efficient use of space in electronic devices, which is increasingly important in modern electronics.

C. Enhanced Thermal Management

The design of magnetic ring inductors facilitates better thermal management. The toroidal shape allows for improved airflow around the inductor, helping to dissipate heat more effectively. This characteristic is crucial in high-power applications where overheating can lead to component failure.

D. Cost-Effectiveness in Mass Production

Magnetic ring inductors can be produced at scale, making them cost-effective for mass production. Their simple design and the availability of materials contribute to lower manufacturing costs, making them an attractive option for manufacturers.

VI. Challenges and Limitations

A. Saturation Effects

One of the challenges associated with magnetic ring inductors is saturation. When the magnetic core reaches its saturation point, the inductor can no longer store additional energy, leading to a decrease in performance. This limitation must be considered when designing circuits that utilize inductors.

B. Frequency Response Limitations

Magnetic ring inductors may exhibit frequency response limitations, particularly at high frequencies. The core material and design can affect the inductor's performance in high-frequency applications, necessitating careful selection based on the specific requirements of the application.

C. Manufacturing Variability

Variability in manufacturing processes can lead to inconsistencies in the performance of magnetic ring inductors. Factors such as material quality, winding techniques, and core construction can all impact the final product, making it essential for manufacturers to maintain strict quality control.

D. Environmental Considerations

As with many electronic components, environmental considerations are becoming increasingly important. The materials used in magnetic ring inductors must be sourced responsibly, and manufacturers are under pressure to adopt sustainable practices in their production processes.

VII. Future Trends and Innovations

A. Advances in Material Science

The future of magnetic ring inductors is likely to be shaped by advances in material science. New materials with improved magnetic properties could lead to more efficient and compact inductors, enhancing their performance across various applications.

B. Integration with Smart Technologies

As the demand for smart technologies continues to grow, magnetic ring inductors will play a crucial role in enabling these innovations. Their ability to efficiently manage power and signals will be essential in the development of smart devices and systems.

C. Miniaturization and Enhanced Performance

The trend toward miniaturization in electronics will drive the development of smaller and more efficient magnetic ring inductors. Innovations in design and materials will enable manufacturers to create inductors that meet the demands of increasingly compact electronic devices.

D. Sustainability in Manufacturing Processes

Sustainability will be a key focus in the future of magnetic ring inductor manufacturing. Companies will need to adopt environmentally friendly practices, such as using recyclable materials and reducing waste, to meet regulatory requirements and consumer expectations.

VIII. Conclusion

Magnetic ring inductors are essential components in modern electronics, playing a vital role in power supply circuits, signal processing, RF applications, and energy storage systems. Their unique design and efficiency make them a preferred choice for many applications. As technology continues to evolve, magnetic ring inductors will remain at the forefront of innovation, adapting to meet the demands of future electronic devices. The ongoing advancements in materials, integration with smart technologies, and a focus on sustainability will shape the future of inductor technology, ensuring that magnetic ring inductors continue to play a crucial role in practical applications.

IX. References

- Academic Journals

- Industry Reports

- Technical Manuals and Guides

This blog post provides a comprehensive overview of the role of magnetic ring inductors in practical applications, highlighting their importance in modern electronics and the trends shaping their future.