What are the Main Application Directions for Inductor Production?

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. As technology continues to advance, the demand for inductors is growing across multiple industries, driven by the increasing complexity and miniaturization of electronic devices. This blog post will explore the main application directions for inductor production, highlighting their significance in consumer electronics, automotive, telecommunications, industrial applications, renewable energy, and medical devices.

II. Types of Inductors

Before delving into the application areas, it is essential to understand the different types of inductors available in the market:

A. Air-core Inductors

These inductors do not use a magnetic core, relying solely on air as the medium. They are typically used in high-frequency applications due to their low losses.

B. Iron-core Inductors

Iron-core inductors utilize an iron core to enhance inductance. They are commonly used in power applications where higher inductance values are required.

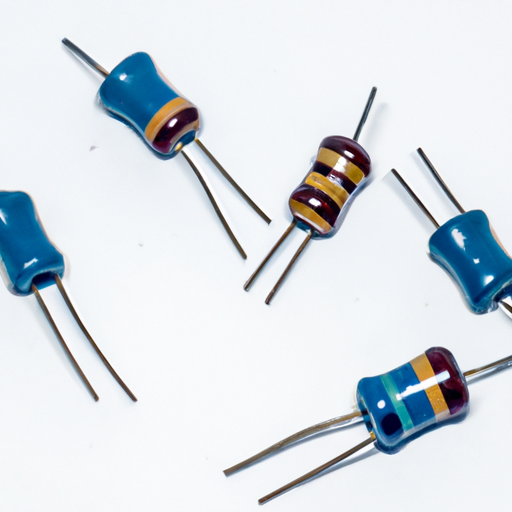

C. Ferrite-core Inductors

Ferrite-core inductors are made with ferrite materials, which provide high magnetic permeability. They are widely used in high-frequency applications, such as RF circuits.

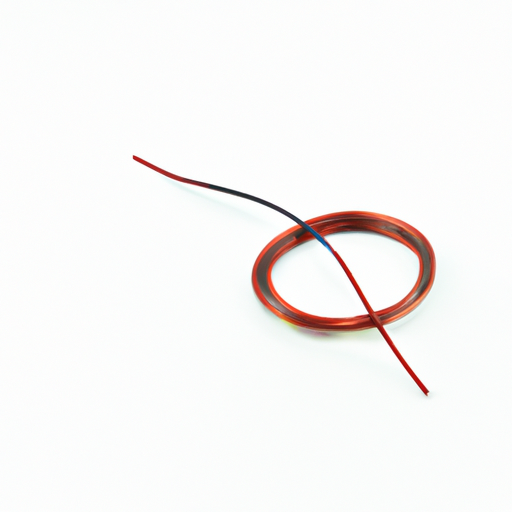

D. Toroidal Inductors

These inductors have a doughnut-shaped core, which minimizes electromagnetic interference and enhances efficiency. They are often used in power supplies and audio equipment.

E. Other Specialized Inductors

This category includes various inductors designed for specific applications, such as choke inductors, coupled inductors, and variable inductors.

III. Key Application Areas for Inductor Production

A. Consumer Electronics

The consumer electronics sector is one of the largest markets for inductors. With the proliferation of smartphones, tablets, laptops, and wearable devices, the demand for compact and efficient inductors has surged.

1. **Smartphones and Tablets**: Inductors are used in power management circuits, audio systems, and RF applications, ensuring optimal performance and energy efficiency.

2. **Laptops and Desktops**: In these devices, inductors play a vital role in power supply units, helping to regulate voltage and current for various components.

3. **Wearable Devices**: As wearables become more sophisticated, the need for miniaturized inductors that can handle high frequencies and low power consumption is increasing.

B. Automotive Industry

The automotive sector is undergoing a significant transformation with the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). Inductors are essential in these applications.

1. **Electric Vehicles (EVs)**: Inductors are used in power converters, battery management systems, and charging stations, contributing to the efficiency and performance of EVs.

2. **Advanced Driver-Assistance Systems (ADAS)**: These systems rely on inductors for signal processing and power management, enhancing safety and functionality.

3. **Infotainment Systems**: Inductors are crucial in audio and video systems within vehicles, ensuring high-quality sound and reliable performance.

C. Telecommunications

The telecommunications industry is rapidly evolving, particularly with the rollout of 5G technology. Inductors are integral to various telecommunications equipment.

1. **Base Stations**: Inductors are used in power amplifiers and filters, ensuring efficient signal transmission and reception.

2. **5G Technology**: The high-frequency requirements of 5G networks necessitate advanced inductors that can handle increased data rates and reduced latency.

3. **Networking Equipment**: Inductors are essential in routers, switches, and other networking devices, helping to manage power and signal integrity.

D. Industrial Applications

Inductors are widely used in industrial settings, where they contribute to automation, control systems, and power supplies.

1. **Power Supplies**: Inductors are critical components in switch-mode power supplies, helping to regulate voltage and current.

2. **Automation and Control Systems**: Inductors are used in sensors and actuators, enabling precise control in manufacturing processes.

3. **Robotics**: In robotics, inductors are essential for power management and signal processing, ensuring reliable operation.

E. Renewable Energy

The shift towards renewable energy sources has created new opportunities for inductor production.

1. **Solar Inverters**: Inductors are used in solar inverters to convert DC power from solar panels into AC power for the grid.

2. **Wind Energy Systems**: Inductors play a role in power conversion and management in wind turbines, enhancing efficiency and reliability.

3. **Energy Storage Systems**: Inductors are essential in battery management systems, helping to regulate charging and discharging processes.

F. Medical Devices

The medical industry relies on inductors for various applications, ensuring the reliability and accuracy of diagnostic and therapeutic equipment.

1. **Diagnostic Equipment**: Inductors are used in imaging systems, such as MRI machines, to manage power and signal integrity.

2. **Imaging Systems**: Inductors play a crucial role in ultrasound and X-ray machines, ensuring high-quality imaging.

3. **Wearable Health Monitors**: As health monitoring devices become more prevalent, the demand for compact and efficient inductors is increasing.

IV. Emerging Trends in Inductor Production

As technology evolves, several trends are shaping the future of inductor production:

A. Miniaturization and High-Density Designs

The trend towards smaller and more compact electronic devices is driving the demand for miniaturized inductors. Manufacturers are developing high-density designs that can fit into smaller spaces without compromising performance.

B. Increased Efficiency and Performance

There is a growing emphasis on producing inductors that offer higher efficiency and performance. This includes reducing losses and improving thermal management to enhance overall system performance.

C. Use of Advanced Materials

Innovative materials, such as nanocrystalline and amorphous alloys, are being explored to improve the performance of inductors. These materials can enhance magnetic properties and reduce size.

D. Customization and Application-Specific Inductors

As industries become more specialized, there is a rising demand for customized inductors tailored to specific applications. Manufacturers are increasingly offering application-specific solutions to meet unique requirements.

V. Challenges in Inductor Production

Despite the growing demand for inductors, several challenges persist in their production:

A. Material Sourcing and Cost

The availability and cost of raw materials can impact the production of inductors. Manufacturers must navigate supply chain challenges to ensure consistent quality and pricing.

B. Manufacturing Precision and Quality Control

Maintaining high precision and quality control in the manufacturing process is crucial. Any deviations can lead to performance issues and increased failure rates.

C. Environmental Regulations and Sustainability

As environmental concerns grow, manufacturers must comply with regulations and adopt sustainable practices in their production processes.

D. Competition and Market Dynamics

The inductor market is highly competitive, with numerous players vying for market share. Manufacturers must innovate and differentiate their products to stay ahead.

VI. Future Directions and Innovations

The future of inductor production is promising, with several exciting directions on the horizon:

A. Integration with Other Components

There is a trend towards integrating inductors with other passive components, such as capacitors and resistors, to create compact, multifunctional modules.

B. Smart Inductors and IoT Applications

The rise of the Internet of Things (IoT) is driving the development of smart inductors that can communicate and adapt to changing conditions, enhancing system performance.

C. Research and Development in New Materials and Technologies

Ongoing research into new materials and manufacturing techniques will continue to push the boundaries of inductor performance, enabling new applications and capabilities.

VII. Conclusion

Inductors are essential components in a wide range of applications, from consumer electronics to renewable energy systems. As technology advances, the demand for inductors is expected to grow, driven by the need for efficiency, miniaturization, and customization. The future of inductor production is bright, with emerging trends and innovations paving the way for new possibilities. As industries continue to evolve, further research and innovation in the field of inductors will be crucial to meet the demands of an increasingly complex technological landscape.