How Should Spot Capacitor Applications Be Selected?

I. Introduction

In the world of electronics, capacitors play a crucial role in various applications, from power supply systems to signal processing. Among these, spot capacitors are specialized components designed for specific tasks within a circuit. Understanding how to select the right spot capacitor for a given application is essential for ensuring optimal performance and reliability. This article will delve into the intricacies of spot capacitors, their applications, and the factors that influence their selection.

II. Understanding Spot Capacitors

A. What are Spot Capacitors?

Spot capacitors are capacitors that are strategically placed within a circuit to perform specific functions. They can be categorized into several types, each with unique characteristics that make them suitable for particular applications.

1. **Types of Spot Capacitors**: The most common types include film capacitors, ceramic capacitors, electrolytic capacitors, and tantalum capacitors. Each type has its own advantages and disadvantages, making it essential to choose the right one based on the application requirements.

2. **Key Characteristics**: Spot capacitors are characterized by their capacitance value, voltage rating, equivalent series resistance (ESR), and ripple current rating. These parameters are critical in determining how well a capacitor will perform in a specific application.

B. Applications of Spot Capacitors

Spot capacitors serve various functions in electronic circuits, including:

1. **Power Factor Correction**: Capacitors are used to improve the power factor in electrical systems, reducing energy losses and improving efficiency.

2. **Voltage Regulation**: They help stabilize voltage levels in power supplies, ensuring that electronic devices receive a consistent voltage.

3. **Energy Storage**: Spot capacitors can store energy for short periods, providing bursts of power when needed.

4. **Filtering Applications**: Capacitors are essential in filtering out unwanted noise and smoothing voltage fluctuations in power supplies and signal processing circuits.

III. Factors Influencing Selection of Spot Capacitors

When selecting spot capacitors, several factors must be considered to ensure optimal performance.

A. Electrical Specifications

1. **Voltage Rating**: The voltage rating of a capacitor indicates the maximum voltage it can handle without failing. It is crucial to select a capacitor with a voltage rating higher than the maximum voltage it will encounter in the application.

2. **Capacitance Value**: The capacitance value determines how much charge a capacitor can store. It is essential to choose a value that meets the specific needs of the application.

3. **Ripple Current Rating**: This rating indicates the maximum current a capacitor can handle without overheating. Selecting a capacitor with an appropriate ripple current rating is vital for applications with fluctuating currents.

B. Environmental Considerations

1. **Temperature Range**: Capacitors have specified operating temperature ranges. Selecting a capacitor that can withstand the environmental conditions of the application is crucial for reliability.

2. **Humidity and Moisture Resistance**: In applications exposed to moisture, it is essential to choose capacitors with adequate humidity resistance to prevent failure.

3. **Mechanical Stress and Vibration**: Capacitors used in environments with high mechanical stress or vibration should be selected based on their ability to withstand these conditions.

C. Application-Specific Requirements

1. **Frequency Response**: Different applications may require capacitors to perform well at specific frequencies. Understanding the frequency response is essential for selecting the right capacitor.

2. **Load Characteristics**: The nature of the load (resistive, inductive, or capacitive) will influence the choice of capacitor.

3. **Lifetime and Reliability**: Consideration of the expected lifetime and reliability of the capacitor is crucial, especially in critical applications.

IV. Evaluating Application Needs

A. Identifying the Purpose of the Capacitor

1. **Power Quality Improvement**: If the goal is to enhance power quality, the selection of capacitors should focus on those that can effectively filter and stabilize voltage.

2. **Energy Efficiency**: For applications aimed at improving energy efficiency, capacitors that support power factor correction and energy storage should be prioritized.

B. Assessing System Requirements

1. **Load Analysis**: Conducting a thorough load analysis helps determine the appropriate capacitance value and type of capacitor needed.

2. **System Configuration**: Understanding the overall system configuration is essential for selecting capacitors that will integrate seamlessly into the design.

C. Considering Future Expansion

1. **Scalability**: When selecting capacitors, consider whether the system may need to be expanded in the future. Choosing capacitors that can accommodate potential growth is wise.

2. **Compatibility with Existing Systems**: Ensure that the selected capacitors are compatible with existing components to avoid integration issues.

V. Types of Spot Capacitors and Their Applications

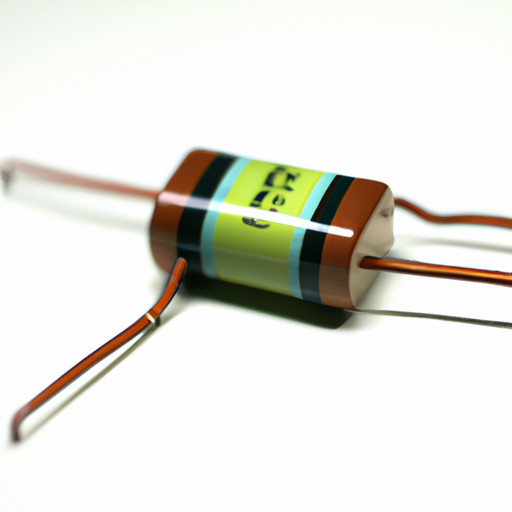

A. Film Capacitors

1. **Characteristics and Benefits**: Film capacitors are known for their stability, low ESR, and high insulation resistance. They are suitable for applications requiring high reliability.

2. **Typical Applications**: Commonly used in power electronics, audio equipment, and signal processing.

B. Ceramic Capacitors

1. **Characteristics and Benefits**: Ceramic capacitors are compact, have a wide capacitance range, and are suitable for high-frequency applications.

2. **Typical Applications**: Often used in decoupling, filtering, and timing applications.

C. Electrolytic Capacitors

1. **Characteristics and Benefits**: Electrolytic capacitors offer high capacitance values in a relatively small package but have polarity and limited lifespan.

2. **Typical Applications**: Widely used in power supply circuits and energy storage applications.

D. Tantalum Capacitors

1. **Characteristics and Benefits**: Tantalum capacitors are known for their high capacitance per volume and stability over time.

2. **Typical Applications**: Commonly used in portable electronics and applications requiring compact size and reliability.

VI. Best Practices for Selecting Spot Capacitors

A. Conducting a Thorough Analysis

1. **Simulation and Modeling**: Utilize simulation tools to model the circuit and predict capacitor performance under various conditions.

2. **Testing and Prototyping**: Building prototypes and conducting tests can provide valuable insights into capacitor performance in real-world scenarios.

B. Consulting Manufacturer Specifications

1. **Understanding Datasheets**: Familiarize yourself with capacitor datasheets to understand the specifications and limitations of each component.

2. **Manufacturer Support and Resources**: Leverage manufacturer resources for guidance on selecting the right capacitors for specific applications.

C. Collaborating with Engineers and Technicians

1. **Interdisciplinary Approach**: Collaborate with engineers and technicians from various disciplines to gather diverse insights and expertise.

2. **Importance of Team Input**: Engaging the team in the selection process can lead to more informed decisions and better outcomes.

VII. Common Mistakes in Spot Capacitor Selection

A. Overlooking Environmental Factors

Failing to consider environmental conditions can lead to premature capacitor failure.

B. Ignoring Application-Specific Needs

Not addressing the specific requirements of the application can result in suboptimal performance.

C. Failing to Consider Long-Term Performance

Neglecting long-term reliability can lead to unexpected failures and increased maintenance costs.

D. Underestimating the Importance of Quality

Choosing low-quality capacitors to save costs can lead to significant issues down the line.

VIII. Conclusion

Selecting the right spot capacitor for an application is a multifaceted process that requires careful consideration of various factors, including electrical specifications, environmental conditions, and application-specific needs. By understanding the characteristics of different types of capacitors and following best practices, engineers can make informed decisions that enhance the performance and reliability of their systems. Continuous learning and adaptation are essential in this ever-evolving field, ensuring that professionals remain equipped to tackle new challenges and innovations.

IX. References

A. Suggested Reading

- "Capacitor Technology and Applications" by John Smith

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

B. Industry Standards and Guidelines

- IEC 60384: Fixed capacitors for use in electronic equipment

- IEEE 18: Standard for the Measurement of Power Capacitors

C. Manufacturer Resources

- Manufacturer datasheets and application notes

- Technical support from capacitor manufacturers

By following this guide, you can navigate the complexities of spot capacitor selection and ensure that your applications are both efficient and reliable.