The Latest Specifications of High Voltage Shunt Capacitors

I. Introduction

High voltage shunt capacitors are essential components in modern electrical systems, playing a crucial role in enhancing the efficiency and stability of power networks. These capacitors are designed to operate at high voltage levels, providing various benefits such as power factor correction, voltage stabilization, and harmonic filtering. This article aims to explore the latest specifications of high voltage shunt capacitors, highlighting their importance, applications, and recent technological advancements.

II. Overview of High Voltage Shunt Capacitors

A. Function and Applications

High voltage shunt capacitors serve multiple functions in electrical systems:

1. **Power Factor Correction**: By improving the power factor, these capacitors help reduce energy losses and enhance the overall efficiency of power systems. A better power factor leads to lower electricity costs and improved system performance.

2. **Voltage Stabilization**: Shunt capacitors help maintain voltage levels within acceptable limits, ensuring the reliable operation of electrical equipment. They can absorb excess reactive power during peak loads, preventing voltage drops.

3. **Harmonic Filtering**: High voltage shunt capacitors can mitigate harmonic distortion in power systems, which can lead to overheating and equipment failure. By filtering out unwanted harmonics, they contribute to the overall health of the electrical network.

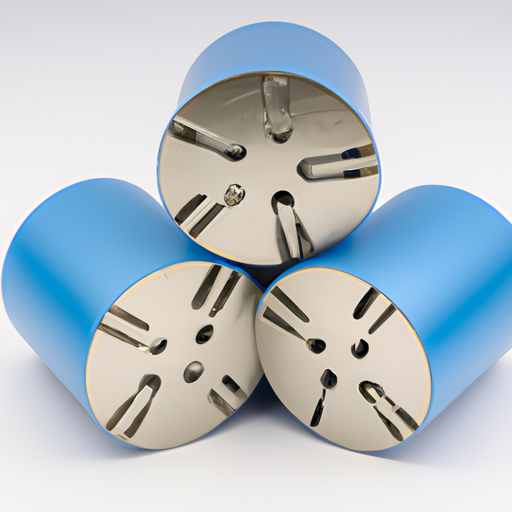

B. Types of High Voltage Shunt Capacitors

There are several types of high voltage shunt capacitors, each designed for specific applications:

1. **Fixed Capacitors**: These capacitors have a predetermined capacitance value and are commonly used in power factor correction applications.

2. **Automatic Capacitors**: Equipped with control systems, these capacitors can adjust their capacitance based on real-time system conditions, providing dynamic power factor correction.

3. **Series Capacitors**: Used primarily in transmission lines, series capacitors help improve voltage stability and increase transmission capacity.

III. Key Specifications of High Voltage Shunt Capacitors

Understanding the specifications of high voltage shunt capacitors is crucial for selecting the right component for a specific application. Here are the key specifications to consider:

A. Voltage Rating

1. **Definition and Importance**: The voltage rating indicates the maximum voltage the capacitor can handle without failure. It is a critical specification that ensures the safety and reliability of the capacitor in high voltage applications.

2. **Common Voltage Ratings**: High voltage shunt capacitors are available in various voltage ratings, including 5kV, 10kV, and 15kV. Selecting the appropriate voltage rating is essential to prevent breakdown and ensure optimal performance.

B. Capacitance Value

1. **Measurement Units**: Capacitance is measured in Farads, with high voltage shunt capacitors typically rated in microfarads (µF).

2. **Typical Capacitance Ranges**: The capacitance values for high voltage shunt capacitors can vary widely, often ranging from a few microfarads to several hundred microfarads, depending on the application.

C. Power Factor

1. **Definition and Relevance**: The power factor is a measure of how effectively electrical power is being converted into useful work output. A power factor close to 1 indicates efficient usage of electrical power.

2. **Acceptable Power Factor Values**: For high voltage shunt capacitors, an acceptable power factor typically ranges from 0.95 to 1.0. Capacitors with higher power factors are preferred for better efficiency.

D. Temperature Rating

1. **Impact of Temperature on Performance**: Temperature can significantly affect the performance and lifespan of high voltage shunt capacitors. High temperatures can lead to dielectric breakdown and reduced capacitance.

2. **Standard Temperature Ratings**: Most high voltage shunt capacitors are rated for operation in temperature ranges from -40°C to +85°C, ensuring reliable performance in various environmental conditions.

E. Insulation Material

1. **Types of Insulation**: Common insulation materials for high voltage shunt capacitors include polypropylene and paper. The choice of insulation material affects the capacitor's performance, reliability, and lifespan.

2. **Importance of Insulation**: Proper insulation is critical in high voltage applications to prevent electrical breakdown and ensure safety. High-quality insulation materials can enhance the capacitor's durability and performance.

IV. Recent Advances in High Voltage Shunt Capacitor Technology

The field of high voltage shunt capacitors has seen significant advancements in recent years, driven by the need for improved performance and sustainability.

A. Improved Materials and Manufacturing Techniques

1. **Enhanced Dielectric Materials**: The development of advanced dielectric materials has led to capacitors with higher voltage ratings and improved thermal stability. These materials can withstand higher temperatures and provide better performance.

2. **Advances in Production Processes**: Modern manufacturing techniques, such as automated winding and precision assembly, have improved the consistency and quality of high voltage shunt capacitors.

B. Smart Capacitor Technology

1. **Integration with IoT and Smart Grids**: The integration of high voltage shunt capacitors with Internet of Things (IoT) technology allows for real-time monitoring and control. This capability enhances the efficiency of power systems and enables proactive maintenance.

2. **Benefits of Real-Time Monitoring**: Real-time monitoring can help identify potential issues before they lead to failures, reducing downtime and maintenance costs.

C. Environmental Considerations

1. **Eco-friendly Materials**: There is a growing emphasis on using environmentally friendly materials in the production of high voltage shunt capacitors. This shift is driven by regulatory requirements and consumer demand for sustainable products.

2. **Recycling and Disposal Practices**: Manufacturers are increasingly adopting recycling practices for capacitor materials, reducing waste and environmental impact.

V. Standards and Regulations

Adhering to industry standards and regulations is crucial for ensuring the safety and reliability of high voltage shunt capacitors.

A. International Standards

Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) set standards for the design, testing, and performance of high voltage shunt capacitors.

B. Compliance and Testing Procedures

Manufacturers must comply with these standards and undergo rigorous testing procedures to ensure their products meet safety and performance requirements.

C. Importance of Adhering to Standards

Compliance with international standards not only ensures the safety and reliability of high voltage shunt capacitors but also enhances their marketability and acceptance in various industries.

VI. Applications in Various Industries

High voltage shunt capacitors find applications across a wide range of industries, including:

A. Power Generation and Distribution

In power generation and distribution systems, high voltage shunt capacitors are used for power factor correction and voltage stabilization, ensuring efficient operation.

B. Renewable Energy Systems

With the rise of renewable energy sources, high voltage shunt capacitors play a vital role in managing the variability of power generation and maintaining grid stability.

C. Industrial Manufacturing

In industrial settings, these capacitors are used to improve power quality and reduce energy costs, contributing to overall operational efficiency.

D. Transportation and Electric Vehicles

High voltage shunt capacitors are increasingly used in electric vehicles and transportation systems to enhance energy efficiency and performance.

VII. Challenges and Considerations

While high voltage shunt capacitors offer numerous benefits, there are also challenges to consider:

A. Reliability and Longevity

Ensuring the reliability and longevity of high voltage shunt capacitors is critical, as failures can lead to significant downtime and repair costs.

B. Cost Factors

The initial cost of high voltage shunt capacitors can be high, but the long-term savings from improved efficiency and reduced energy costs often justify the investment.

C. Maintenance and Monitoring Needs

Regular maintenance and monitoring are essential to ensure the optimal performance of high voltage shunt capacitors, requiring investment in monitoring technology and skilled personnel.

VIII. Conclusion

High voltage shunt capacitors are vital components in modern electrical systems, providing essential functions such as power factor correction, voltage stabilization, and harmonic filtering. Understanding their specifications, recent technological advancements, and applications across various industries is crucial for selecting the right capacitor for specific needs. As the demand for efficient and reliable electrical systems continues to grow, high voltage shunt capacitors will play an increasingly important role in shaping the future of power management.

IX. References

A comprehensive list of academic journals, industry reports, and standards related to high voltage shunt capacitors can provide further insights and information for those interested in exploring this topic in greater depth.