What Kind of Product Are Ceramic Capacitors?

I. Introduction

A. Definition of Ceramic Capacitors

Ceramic capacitors are passive electronic components that store electrical energy in an electric field. They are made from ceramic materials that act as dielectric insulators, allowing them to hold charge when a voltage is applied. These capacitors are widely used in various electronic circuits due to their unique properties and versatility.

B. Importance of Capacitors in Electronic Circuits

Capacitors play a crucial role in electronic circuits by performing functions such as energy storage, filtering, coupling, and decoupling. They help stabilize voltage and power flow, making them essential for the proper functioning of electronic devices. Among the different types of capacitors, ceramic capacitors are particularly favored for their reliability and performance.

C. Overview of the Article

This article will delve into the world of ceramic capacitors, exploring their composition, types, advantages, limitations, applications, and future trends. By the end, readers will have a comprehensive understanding of what ceramic capacitors are and their significance in modern electronics.

II. Understanding Capacitors

A. Basic Principles of Capacitance

1. Definition of Capacitance

Capacitance is the ability of a component to store an electrical charge. It is defined as the ratio of the electric charge (Q) stored on one plate of the capacitor to the voltage (V) across the plates. The unit of capacitance is the farad (F), which is a large unit; most capacitors used in practical applications are measured in microfarads (µF), nanofarads (nF), or picofarads (pF).

2. How Capacitors Store Energy

When a voltage is applied across the plates of a capacitor, an electric field is created, causing positive and negative charges to accumulate on opposite plates. This stored energy can be released when needed, making capacitors essential for various applications, including power supply smoothing and signal coupling.

B. Types of Capacitors

Capacitors come in various types, each with distinct characteristics and applications. The most common types include:

1. Electrolytic Capacitors

These capacitors are polarized and typically used for high-capacitance applications, such as power supply filtering. They have a larger capacitance value but are limited in terms of voltage and temperature stability.

2. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their stability and low loss, making them suitable for audio and high-frequency applications.

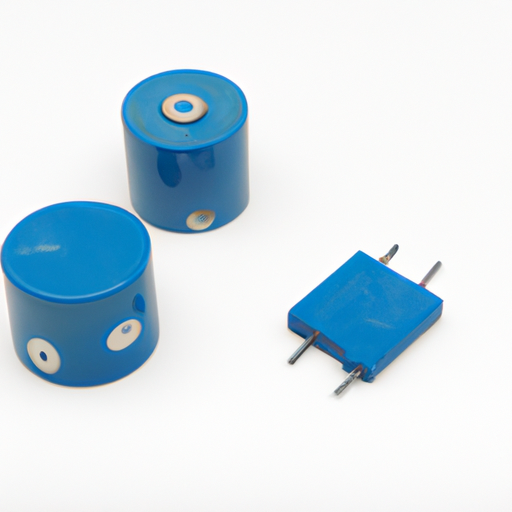

3. Ceramic Capacitors

Ceramic capacitors are non-polarized and are made from ceramic materials. They are widely used in various electronic applications due to their small size, reliability, and cost-effectiveness.

C. Applications of Capacitors in Electronics

Capacitors are used in a wide range of applications, including power supply circuits, signal processing, timing circuits, and energy storage systems. Their ability to store and release energy makes them indispensable in modern electronics.

III. What Are Ceramic Capacitors?

A. Composition and Structure

1. Materials Used in Ceramic Capacitors

Ceramic capacitors are primarily made from ceramic materials, which serve as the dielectric. Common materials include barium titanate and other ferroelectric ceramics, which provide high permittivity and stability.

2. Types of Ceramic Dielectrics

Ceramic capacitors are categorized based on their dielectric properties into two main classes: Class 1 and Class 2. Class 1 dielectrics offer stable capacitance with temperature and voltage changes, while Class 2 dielectrics provide higher capacitance values but with less stability.

B. Manufacturing Process

1. Steps in Producing Ceramic Capacitors

The manufacturing process of ceramic capacitors involves several steps, including mixing raw materials, forming the dielectric layer, applying electrodes, and sintering the components at high temperatures. This process ensures the desired electrical properties and reliability.

2. Quality Control Measures

Quality control is critical in the production of ceramic capacitors. Manufacturers conduct rigorous testing to ensure that the capacitors meet specified standards for capacitance, voltage rating, and temperature stability.

IV. Types of Ceramic Capacitors

A. Class 1 Ceramic Capacitors

1. Characteristics and Applications

Class 1 ceramic capacitors are known for their stability and low loss. They exhibit minimal capacitance variation with temperature and voltage changes, making them ideal for precision applications such as timing circuits and RF applications.

2. Common Uses in Circuits

These capacitors are commonly used in oscillators, filters, and coupling applications where stability is crucial.

B. Class 2 Ceramic Capacitors

1. Characteristics and Applications

Class 2 ceramic capacitors offer higher capacitance values but have a greater variation in capacitance with temperature and voltage. They are suitable for applications where size and capacitance are more critical than stability.

2. Common Uses in Circuits

These capacitors are often used in decoupling applications, power supply circuits, and consumer electronics.

C. Comparison Between Class 1 and Class 2

The primary difference between Class 1 and Class 2 ceramic capacitors lies in their stability and capacitance values. Class 1 capacitors are preferred for precision applications, while Class 2 capacitors are chosen for their higher capacitance in compact designs.

V. Advantages of Ceramic Capacitors

A. Size and Form Factor

Ceramic capacitors are available in small sizes, making them ideal for compact electronic devices. Their small form factor allows for high-density circuit designs.

B. Stability and Reliability

Ceramic capacitors exhibit excellent stability over a wide range of temperatures and voltages, ensuring reliable performance in various applications.

C. Temperature and Voltage Characteristics

These capacitors can operate effectively across a broad temperature range and can handle high voltages, making them suitable for demanding environments.

D. Cost-Effectiveness

Ceramic capacitors are generally more affordable than other types, such as electrolytic or film capacitors, making them a cost-effective choice for manufacturers.

VI. Limitations of Ceramic Capacitors

A. Voltage Coefficient

One limitation of ceramic capacitors, particularly Class 2 types, is the voltage coefficient, which can lead to a significant decrease in capacitance at higher voltages.

B. Dielectric Absorption

Ceramic capacitors can exhibit dielectric absorption, where they retain some charge after being discharged, potentially affecting circuit performance.

C. Microphonics and Mechanical Sensitivity

Ceramic capacitors can be sensitive to mechanical vibrations, leading to microphonics, which can introduce noise in audio applications.

D. Limited Capacitance Values

While ceramic capacitors are available in various capacitance values, they may not reach the high capacitance levels offered by electrolytic capacitors, limiting their use in certain applications.

VII. Applications of Ceramic Capacitors

A. Consumer Electronics

1. Smartphones and Tablets

Ceramic capacitors are widely used in smartphones and tablets for decoupling and filtering applications, ensuring stable power supply and signal integrity.

2. Laptops and Desktops

In laptops and desktops, ceramic capacitors are employed in power management circuits, audio systems, and high-frequency applications.

B. Automotive Industry

Ceramic capacitors are increasingly used in automotive electronics for applications such as engine control units, infotainment systems, and safety features.

C. Industrial Equipment

In industrial settings, ceramic capacitors are utilized in motor drives, power supplies, and control systems, where reliability and performance are critical.

D. Telecommunications

Ceramic capacitors play a vital role in telecommunications equipment, ensuring signal integrity and stability in high-frequency applications.

E. Medical Devices

In medical devices, ceramic capacitors are used for their reliability and stability, ensuring accurate performance in critical applications.

VIII. Future Trends in Ceramic Capacitor Technology

A. Innovations in Materials and Design

The future of ceramic capacitors lies in the development of new materials and designs that enhance performance, reduce size, and improve reliability.

B. Increasing Demand in Emerging Technologies

As technology advances, the demand for ceramic capacitors in emerging fields such as electric vehicles, renewable energy, and IoT devices is expected to grow.

C. Environmental Considerations and Sustainability

Manufacturers are increasingly focusing on sustainable practices and materials in the production of ceramic capacitors, aligning with global efforts to reduce environmental impact.

IX. Conclusion

A. Recap of Key Points

Ceramic capacitors are essential components in modern electronics, offering a unique combination of size, stability, and cost-effectiveness. Understanding their properties and applications is crucial for anyone involved in electronics design and manufacturing.

B. The Role of Ceramic Capacitors in Modern Electronics

As technology continues to evolve, ceramic capacitors will play an increasingly important role in ensuring the performance and reliability of electronic devices.

C. Final Thoughts on the Importance of Understanding Ceramic Capacitors

In conclusion, a thorough understanding of ceramic capacitors is vital for engineers, designers, and manufacturers. Their versatility and reliability make them a cornerstone of modern electronic design, and staying informed about their developments will be key to future innovations.

X. References

A. Academic Journals

- Journal of Electronic Materials

- IEEE Transactions on Components, Packaging and Manufacturing Technology

B. Industry Reports

- Market Research Reports on Capacitor Technologies

- Industry Analysis Reports on Electronic Components

C. Manufacturer Specifications

- Datasheets from leading capacitor manufacturers

- Technical documents on ceramic capacitor technologies

D. Online Resources and Articles

- Electronics tutorials and educational websites

- Blogs and articles from industry experts on capacitor technologies

This comprehensive overview of ceramic capacitors highlights their significance in the electronics industry, providing valuable insights for anyone interested in understanding this essential component.