Market Policies for Film Capacitors

I. Introduction

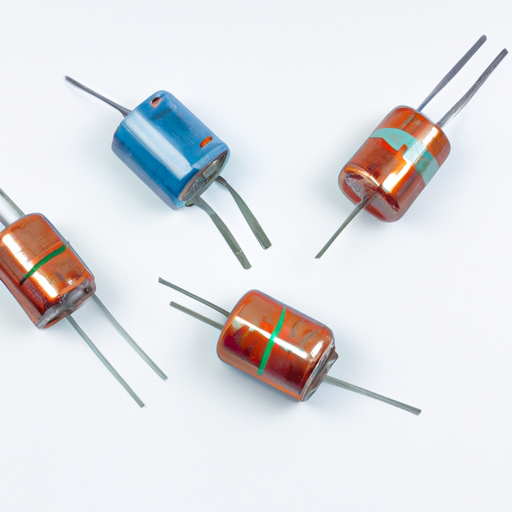

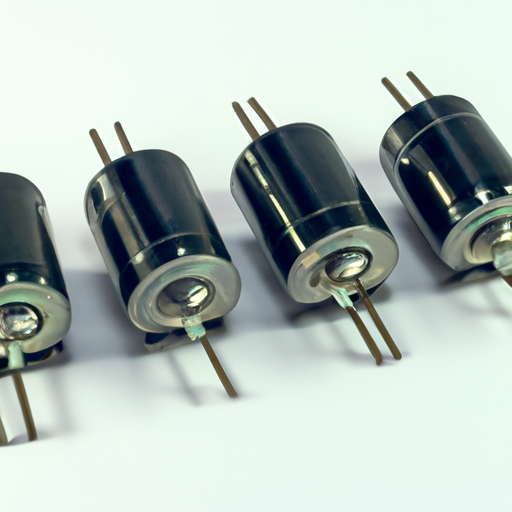

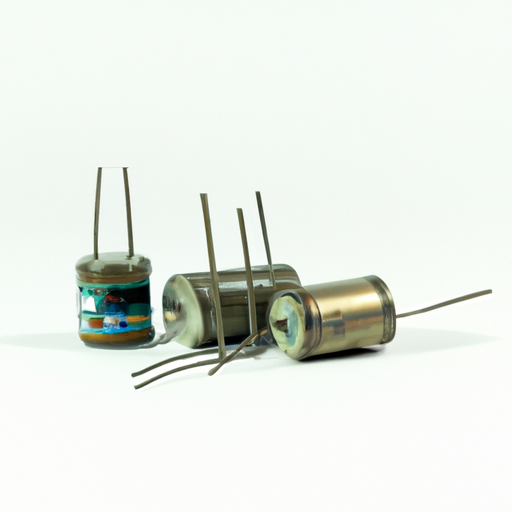

Film capacitors are essential components in the electronics industry, known for their reliability, stability, and versatility. These capacitors utilize a thin plastic film as the dielectric material, making them suitable for a wide range of applications, from consumer electronics to industrial machinery. As the demand for electronic devices continues to grow, understanding the market policies surrounding film capacitors becomes increasingly important. This blog post will explore the various aspects of market policies for film capacitors, including their types, applications, market dynamics, regulatory frameworks, and future trends.

II. Understanding Film Capacitors

A. Types of Film Capacitors

Film capacitors come in several types, each with unique properties and applications:

1. **Polyester Film Capacitors**: These are the most common type of film capacitors, known for their cost-effectiveness and decent performance. They are widely used in applications such as audio equipment, power supplies, and consumer electronics.

2. **Polypropylene Film Capacitors**: Offering superior performance in terms of low loss and high insulation resistance, polypropylene film capacitors are often used in high-frequency applications, such as RF circuits and audio systems.

3. **Polycarbonate Film Capacitors**: Although less common due to their higher cost, polycarbonate film capacitors provide excellent stability and reliability, making them suitable for critical applications in aerospace and military electronics.

B. Applications of Film Capacitors

Film capacitors find applications across various sectors:

1. **Consumer Electronics**: From televisions to smartphones, film capacitors play a crucial role in ensuring the smooth operation of electronic devices.

2. **Industrial Applications**: In industrial settings, these capacitors are used in motor drives, power supplies, and automation systems, where reliability and performance are paramount.

3. **Renewable Energy Systems**: With the growing emphasis on sustainability, film capacitors are increasingly used in renewable energy systems, such as solar inverters and wind turbines, to enhance energy efficiency.

III. Market Dynamics

A. Global Market Overview

The global film capacitor market has witnessed significant growth in recent years. According to industry reports, the market size is expected to continue expanding, driven by technological advancements and increasing demand for energy-efficient solutions. Key players in the film capacitor market include companies like Vishay Intertechnology, KEMET Corporation, and Panasonic, which are continuously innovating to meet the evolving needs of consumers.

B. Demand Drivers

Several factors are driving the demand for film capacitors:

1. **Technological Advancements**: The rapid pace of technological innovation in electronics has led to the development of more sophisticated devices, increasing the need for high-performance capacitors.

2. **Increasing Demand for Energy Efficiency**: As industries and consumers alike seek to reduce energy consumption, film capacitors are becoming essential components in energy-efficient designs.

3. **Growth in Renewable Energy Sector**: The shift towards renewable energy sources has created a surge in demand for film capacitors, particularly in applications related to solar and wind energy.

C. Challenges in the Market

Despite the positive outlook, the film capacitor market faces several challenges:

1. **Competition from Alternative Capacitor Technologies**: The emergence of alternative capacitor technologies, such as ceramic and electrolytic capacitors, poses a competitive threat to film capacitors.

2. **Supply Chain Disruptions**: Global supply chain issues, exacerbated by the COVID-19 pandemic, have impacted the availability of raw materials and components, affecting production timelines.

3. **Regulatory Compliance**: Adhering to stringent regulatory requirements can be challenging for manufacturers, particularly in terms of environmental standards.

IV. Regulatory Framework

A. International Standards and Certifications

The film capacitor market is governed by various international standards and certifications, ensuring product quality and safety:

1. **IEC Standards**: The International Electrotechnical Commission (IEC) sets standards for electrical and electronic devices, including film capacitors, to ensure their reliability and performance.

2. **UL Certification**: Underwriters Laboratories (UL) certification is crucial for manufacturers looking to enter the North American market, as it signifies compliance with safety standards.

B. Environmental Regulations

Environmental regulations play a significant role in shaping market policies:

1. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electronic products, pushing manufacturers to adopt safer materials in their film capacitors.

2. **WEEE Directive**: The Waste Electrical and Electronic Equipment (WEEE) directive mandates proper disposal and recycling of electronic waste, influencing manufacturers to design more sustainable products.

C. Impact of Regulations on Market Policies

Compliance with these regulations often requires manufacturers to invest in research and development, leading to increased production costs. However, adherence to these standards can also enhance brand reputation and consumer trust, ultimately benefiting companies in the long run.

V. Market Policies and Strategies

A. Pricing Strategies

Pricing strategies are crucial for manufacturers to remain competitive in the film capacitor market:

1. **Cost-Plus Pricing**: This strategy involves calculating the total cost of production and adding a markup to determine the selling price. It ensures that manufacturers cover their costs while making a profit.

2. **Competitive Pricing**: In a competitive market, manufacturers may adopt competitive pricing strategies to attract customers, often adjusting prices based on market trends and competitor pricing.

B. Distribution Policies

Distribution policies play a vital role in reaching target markets:

1. **Direct vs. Indirect Distribution**: Manufacturers can choose between direct distribution, where they sell directly to consumers, or indirect distribution, where they partner with distributors and retailers.

2. **E-commerce and Online Sales Channels**: The rise of e-commerce has transformed distribution strategies, allowing manufacturers to reach a broader audience through online platforms.

C. Marketing Strategies

Effective marketing strategies are essential for brand positioning:

1. **Branding and Positioning**: Establishing a strong brand identity helps manufacturers differentiate their products in a crowded market.

2. **Target Market Segmentation**: Understanding the specific needs of different market segments allows manufacturers to tailor their marketing efforts and product offerings accordingly.

D. Research and Development Policies

Investment in research and development is critical for innovation:

1. **Investment in Innovation**: Manufacturers must allocate resources to develop new technologies and improve existing products to stay ahead of the competition.

2. **Collaboration with Research Institutions**: Partnering with research institutions can facilitate knowledge exchange and accelerate the development of cutting-edge technologies.

VI. Regional Market Policies

A. North America

The North American film capacitor market is characterized by advanced technology and stringent regulations. Key policies include:

1. **Market Characteristics**: The region is home to several leading manufacturers and a strong demand for high-performance capacitors.

2. **Key Policies and Regulations**: Compliance with UL certification and RoHS directives is essential for manufacturers operating in this market.

B. Europe

Europe is known for its robust environmental policies, influencing market dynamics:

1. **Market Trends**: The demand for eco-friendly products is driving innovation in the film capacitor market.

2. **Environmental Policies**: The WEEE directive and other regulations promote sustainable practices among manufacturers.

C. Asia-Pacific

The Asia-Pacific region is experiencing rapid growth in the film capacitor market:

1. **Rapid Growth and Emerging Markets**: Countries like China and India are witnessing increased demand for electronic devices, driving the need for film capacitors.

2. **Local Regulations and Standards**: Manufacturers must navigate varying regulations across different countries in the region, impacting their market strategies.

VII. Future Trends and Predictions

A. Technological Innovations

The future of the film capacitor market will be shaped by technological innovations, including advancements in materials and manufacturing processes that enhance performance and reduce costs.

B. Sustainability and Eco-Friendly Practices

As sustainability becomes a priority for consumers and industries alike, manufacturers will need to adopt eco-friendly practices, such as using recyclable materials and reducing waste in production.

C. Market Forecasts

Market forecasts indicate continued growth in the film capacitor sector, driven by increasing demand in consumer electronics, renewable energy, and industrial applications.

VIII. Conclusion

In summary, the market policies for film capacitors are influenced by various factors, including technological advancements, regulatory frameworks, and market dynamics. As the demand for electronic devices continues to rise, manufacturers must adapt to changing market conditions and consumer preferences. By investing in innovation, adhering to regulations, and implementing effective marketing strategies, companies can position themselves for success in the evolving film capacitor market. The future outlook remains positive, with opportunities for growth and development in this essential sector of the electronics industry.