What are the Popular Capacitor Price Product Types?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in storing and releasing electrical energy. They are used in a variety of applications, from power supply smoothing to signal coupling and filtering. Understanding the different types of capacitors and their price ranges is essential for engineers, hobbyists, and anyone involved in electronics. This article aims to explore the popular types of capacitors, their applications, and the factors that influence their pricing.

II. Understanding Capacitors

A. Basic Principles of Capacitors

Capacitors function by storing electrical energy in an electric field, created between two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric charge accumulates, allowing the capacitor to store energy. Key specifications of capacitors include:

1. **Capacitance**: Measured in farads (F), capacitance indicates the amount of charge a capacitor can store per volt.

2. **Voltage Rating**: This is the maximum voltage a capacitor can handle before it risks breakdown.

3. **Tolerance**: This refers to the variation in capacitance from the stated value, expressed as a percentage.

B. Types of Capacitors Based on Materials and Construction

Capacitors can be categorized based on their materials and construction methods. The most common types include:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors use an electrolyte as one of their plates.

2. **Ceramic Capacitors**: These are made from ceramic materials and are widely used for their stability and reliability.

3. **Film Capacitors**: Constructed from thin plastic films, these capacitors are known for their low losses and high stability.

4. **Tantalum Capacitors**: These are a type of electrolytic capacitor that uses tantalum metal, offering high capacitance in a small package.

5. **Supercapacitors**: Also known as ultracapacitors, these devices can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles.

III. Popular Capacitor Types and Their Price Ranges

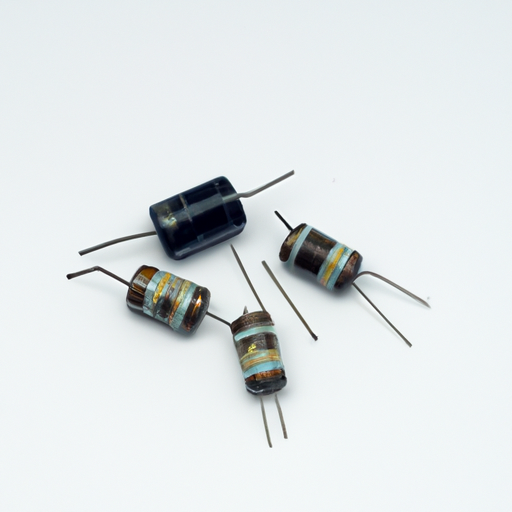

A. Electrolytic Capacitors

Electrolytic capacitors are widely used in power supply circuits due to their high capacitance values, which can range from a few microfarads (µF) to several thousand microfarads. They are typically polarized, meaning they have a positive and negative terminal.

Applications: Commonly found in power supply filters, audio equipment, and decoupling applications.

Price Range: Prices can vary significantly based on capacitance and voltage ratings, typically ranging from $0.10 to $5.00 per unit. Factors affecting cost include the quality of the electrolyte and the manufacturing process.

B. Ceramic Capacitors

Ceramic capacitors are known for their small size and reliability. They are non-polarized and can be used in a variety of applications.

Applications: Used in high-frequency applications, decoupling, and timing circuits.

Price Range: Generally, ceramic capacitors are affordable, with prices ranging from $0.01 to $1.00 per unit, depending on capacitance and voltage ratings.

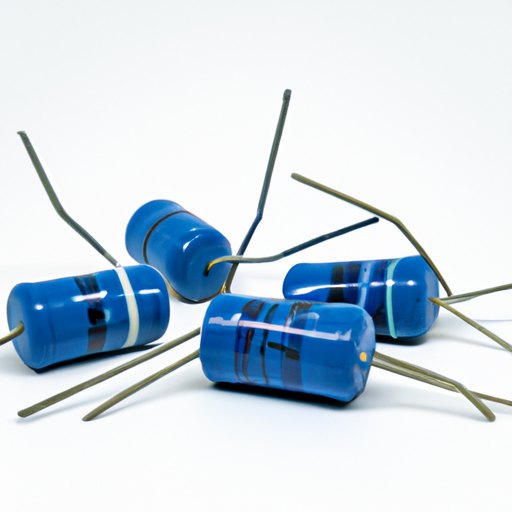

C. Film Capacitors

Film capacitors are appreciated for their stability and low loss characteristics. They are non-polarized and can handle high voltages.

Applications: Commonly used in audio equipment, power electronics, and timing circuits.

Price Range: Prices typically range from $0.10 to $3.00 per unit, influenced by the type of film used and the capacitor's specifications.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance in a small size, making them ideal for compact electronic devices.

Applications: Frequently used in mobile phones, laptops, and other portable electronics.

Price Range: Tantalum capacitors are generally more expensive, with prices ranging from $0.50 to $10.00 per unit, depending on capacitance and voltage ratings.

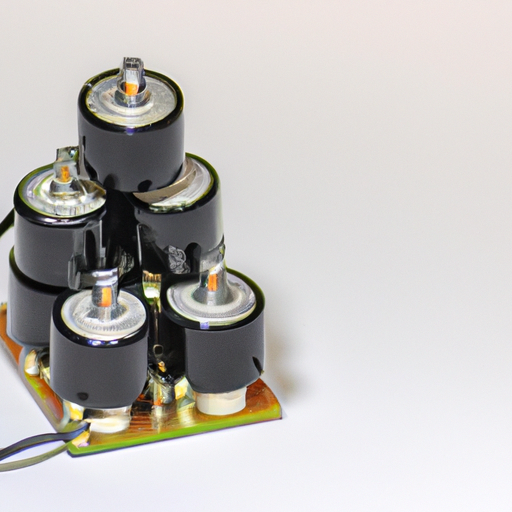

E. Supercapacitors

Supercapacitors are unique in their ability to store large amounts of energy and deliver it quickly, making them suitable for applications requiring rapid charge and discharge cycles.

Applications: Used in energy storage systems, backup power supplies, and regenerative braking systems in electric vehicles.

Price Range: Prices can vary widely, typically ranging from $1.00 to $50.00 per unit, influenced by capacitance, voltage rating, and manufacturer.

IV. Factors Influencing Capacitor Prices

Several factors contribute to the pricing of capacitors:

A. Material Costs

The raw materials used in capacitor production, such as tantalum, aluminum, and ceramic, significantly impact the final price. Fluctuations in the market for these materials can lead to price changes.

B. Manufacturing Processes

The complexity of the manufacturing process also affects costs. For instance, tantalum capacitors require more intricate production techniques compared to ceramic capacitors, leading to higher prices.

C. Market Demand and Supply

The demand for specific types of capacitors can influence pricing. For example, during a surge in electronic device production, the demand for certain capacitors may increase, driving up prices.

D. Brand Reputation and Quality Assurance

Reputable brands often charge more for their products due to established quality assurance processes and reliability. Consumers may be willing to pay a premium for capacitors from trusted manufacturers.

E. Technological Advancements

Innovations in capacitor technology can lead to new products with enhanced performance characteristics, which may come at a higher price point. As technology evolves, older capacitor types may decrease in price as newer alternatives emerge.

V. Comparison of Capacitor Types

When selecting a capacitor, it is essential to consider various factors:

A. Performance Characteristics

Different capacitor types exhibit varying performance characteristics, such as temperature stability, frequency response, and equivalent series resistance (ESR). For example, ceramic capacitors are known for their low ESR, making them suitable for high-frequency applications.

B. Cost-Effectiveness

While some capacitors may have a higher upfront cost, their longevity and reliability can make them more cost-effective in the long run. For instance, film capacitors may be more expensive than electrolytic capacitors but often have a longer lifespan.

C. Application Suitability

Choosing the right capacitor type depends on the specific application. For high-frequency circuits, ceramic capacitors are often preferred, while electrolytic capacitors are better suited for power supply applications.

D. Longevity and Reliability

The lifespan of a capacitor can vary significantly based on its type and application. Tantalum capacitors, for example, are known for their reliability but can fail catastrophically if subjected to overvoltage conditions.

VI. Conclusion

In summary, capacitors are vital components in electronic circuits, and understanding the different types and their price ranges is crucial for making informed decisions. Electrolytic, ceramic, film, tantalum, and supercapacitors each have unique characteristics and applications, with prices influenced by material costs, manufacturing processes, and market demand.

Selecting the right capacitor type involves considering performance characteristics, cost-effectiveness, application suitability, and reliability. As technology continues to advance, we can expect to see new capacitor types and pricing trends emerge, further shaping the landscape of electronic components.

VII. References

1. "Capacitor Basics: What is a Capacitor?" Electronics Tutorials.

2. "Understanding Capacitor Types and Their Applications," Electronic Design.

3. "Market Analysis of Capacitors," Research and Markets.

4. "The Future of Capacitor Technology," IEEE Spectrum.

This comprehensive exploration of popular capacitor types and their price ranges provides valuable insights for anyone involved in electronics, from engineers to hobbyists. By understanding the nuances of each type, individuals can make informed choices that align with their specific needs and budget.