Information

dict2_description

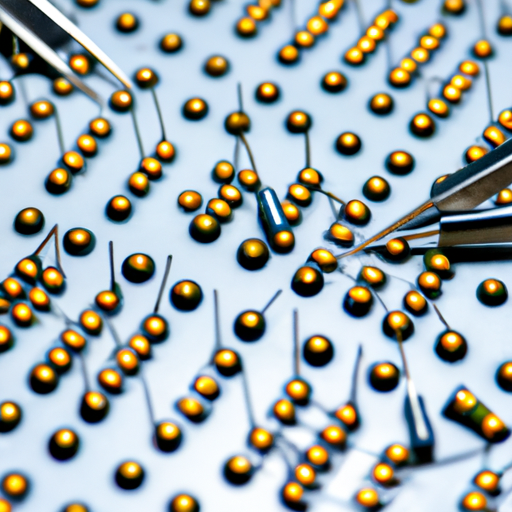

Common inductor functions popular models

2025-03-12

0

How big is the market size of RF inductors?

2025-03-11

0

What kind of product is inductor design?

2025-03-09

1

dict3_title

dict3_description